In the million-year history of mankind, it has always been common to use many tools for various activities. Man is a creature that has lived with industry since the beginning of creation. From the very beginning when it was necessary to make swords and spears until some time later when they turned to building ships and houses until today when countless industries have been created by humans and the wheel of these industries is turning. In these different industries, there have always been elements and tools that have competed with each other for human use. Imagine you are in a blacksmith shop. Suddenly, the blacksmith starts using a brush-like object and polishes the metal. This object is called Gilans. Now, today and in this article, we are going to introduce and fully review Gilans and its difference from sanding. Follow us to the end of the article.

What is Gilans?

Gilans is a type of brush that consists of many layers of felt. Usually, as a standard, the number of layers of gilanses should be between 21 and 24 in order to be able to say that we have a standard gilans. Of course, the quality control of these tools is not limited to the number of these layers. In fact, a lot of attention should be paid to the high quality of these layers. These layers are sewn together with special precision and elegance to create a magical tool for creating beauty. Gilans is actually an intermediary between the blacksmith’s hand and the raw metal. Of course, this does not mean that only blacksmiths use this element. In many industrial units that deal with metals and their polishing, you will notice the presence of gilans. Of course, the introduction of Gilans does not end here.

Gilans uses

Considering the above, you must have realized that these elements can have many benefits and applications. In this section, we are going to discuss the main uses of this element. Stay with us.

Polishing of metals

First of all, we must say that the purpose of metal polishing is to turn metals into a smooth and polished object. Gilans is used to smooth and polish metal surfaces, remove lines and roughness, and create a dazzling shine.

Polishing

All of you are definitely familiar with the polishing process. You know that in this process we polish different surfaces. Along with polishing materials, Gilans is used to polish and shine metal surfaces, such as steel, iron and brass surfaces.

rust removal

One of the things that always threatens metals is destruction due to oxidation and rusting. These calls should be eliminated using solutions. Gilance can be used to remove rust and oxide from metals, and restore their original shine.

Preparation of surfaces for painting

You know that before starting the process of painting any object, it is necessary to clean its surface from additions and irregularities. By creating a smooth and uniform surface, Gilans helps to improve the adhesion of paint and increase the quality of painting.

The difference between gilansand sanding

By introducing this element so far, you might say to yourself that these are exactly the same features of sandpaper. You may ask, what is the difference between Gilans and sandpaper? Do not rush at all. In this section, you will find the answer to your question. Both Gilans and sandpapers are used to polish surfaces. But there are differences. Gilans is used to smooth and polish surfaces and create a shine, while sanding is used to roughen surfaces and remove large irregularities. The second difference is that the sandpaper is made of felt, while the sandpaper is made of paper or cloth covered with abrasive grains. The third difference is in the scope of their applications. Grinding is usually used for metal surfaces, while sandpaper can be used for different surfaces, such as wood, metal, plastic, etc.

Types of gilance

It is natural that gilans have different types. In this section, we intend to introduce the types of Gilans to you.

ساده ترین و پر استفاده ترین نوع از انواع گیلانس است. این مدل از نمد طبیعی ساخته شده است و برای پرداخت سطوح فلزی و سنگی به کار میرود.

This type of polish is made of thick and woven fabrics and is used to polish wooden and plastic surfaces.

If you plan to polish very rough and uneven surfaces, using this model is recommended. This model is made of thin metal wires.

But let’s introduce the most expensive type of Gilans. This model is made of diamond powder and adhesive materials and is used to polish very hard and delicate surfaces.

Note that the selection of the appropriate type and material of gilans depends on various factors such as the material of the desired surface, the level of roughness and unevenness of the surface, and the type of desired polishing operation.

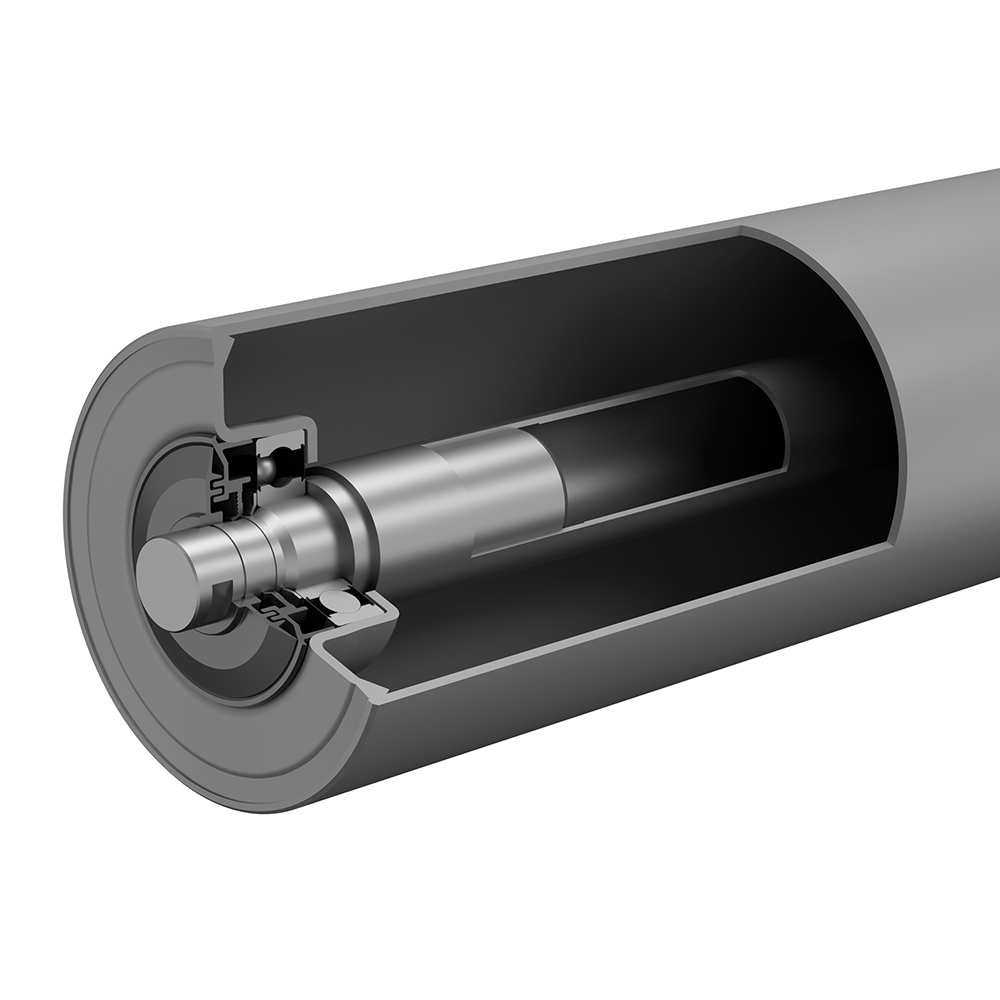

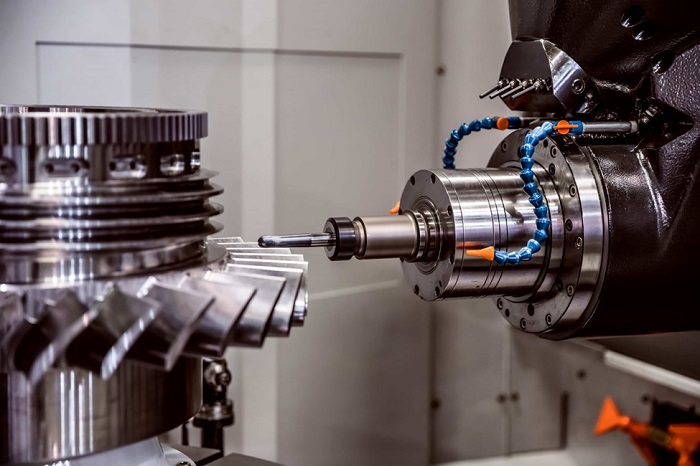

Application of Gilans in grinding

One of the main processes in various industries is the grinding process. Grinding is one of the main activities in many industrial workshops, including the Mabnapaya industrial group, during which many surfaces can be smoothed and polished. Grinding and sanding are two elements that are very useful in grinding. But in this part, we are going to examine Gilans. One of the main advantages of this element in grinding is the polishing of stone surfaces. Gilans is used to smooth and polish various surfaces, such as stone and metals. Another use of this element is sub. Along with sub materials, it is used for polishing and polishing different surfaces. Another use of this element is to create designs and patterns on different surfaces. Gilans can be used to create different designs and roles on different surfaces.

Important points before using Gilans

Like any other activity, using gilans also has a series of principles and prerequisites that we must pay attention to. You can definitely have a better experience using these simple tips. First of all, note that the desired surface must be cleaned of any dirt and grease. Also, Gilans should be moved at a suitable speed and in a circular manner on the desired surface. It is worth noting that to increase the life of Gilans, it should be used and maintained properly. One of the main activities of Mabanapaya Industrial Group is roller grinding and polishing. These processes are sometimes done using gilans. Also, in this industrial unit, we repair and produce all kinds of rollers.

Thank you for joining us in this article. As you have seen, in this article, we introduced and reviewed Gilans and explained its differences with sanding. Gilans is a magical tool to create beauty and shine. This tool, with a long history in history, has always been with craftsmen and artists. Gilans plays elegance and creativity in the fabric of metal and stone and gives them a new life. In a world where beauty comes first, Gilans plays an important role. We see that with every caress of Gilans on the surfaces, light particles are reflected from it and the darkness gives way to a unique shine. This is the shine and attractiveness that glosses give to surfaces. We hope that the material presented in this article was useful to you. You can contact the experts of Mabnapaya Industrial Group for more information.