Today, with the development of technology and the progress of various industries, it is necessary to use auxiliary tools to advance human goals. These tools may be used for different purposes. Construction and production of other parts. Helping to transport other components easily. Helping to make different levels and many other uses. One of the tools that is used today in many main and secondary industries and even in many businesses and workshops is the roller. Rollers are hollow cylinders used in many services. The introduction of rollers is not limited to these few sentences. Today, in this article, we are going to introduce one of the most used objects in various industries. If you are also interested in this topic, we suggest that you accompany us to the end.

What is a roller?

It is a round and flat object that is usually made of metal, plastic or rubber. They are used for various purposes, including power transmission, moving materials, smoothing surfaces, and manufacturing products. Rollers can be used individually or in large groups. Single rollers are usually used for specific purposes such as transmitting power or moving materials. Group rollers are usually used for smoothing surfaces or manufacturing products. Rollers can be connected to other devices in different ways. They can be directly attached to the machine, or they can be attached via a shaft. One of the important uses of rollers in the industry is called polishing rollers. This method is used to smooth and polish metal surfaces.

Advantages of roller

Rollers can definitely have many benefits. The features that we will discuss in the following are comprehensive features for these elements. what does it mean? That is, we say these features regardless of the type of roller. These elements can have many advantages according to their type of use and activity.

- power transmission

- Moving materials

- Smooth surfaces

- Production of products

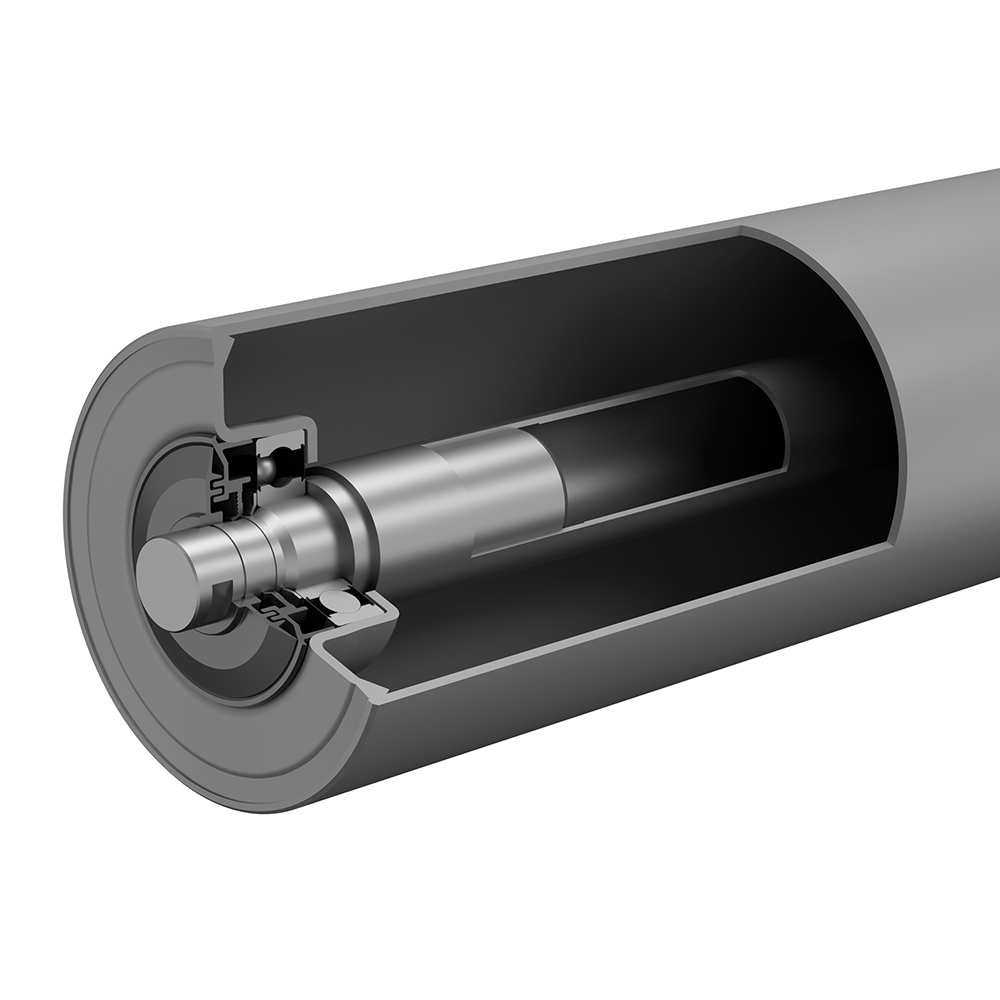

Roller components

Standard rollers usually consist of three main parts. Its main part is the cylinder with the same main body as the roller. The material of this body can determine the use of this roller. For example, steel rollers should be used for farming industries. Or, for example, sanding rollers should be used in polishing industries. Another part used in this element is the shaft. The shafts are responsible for helping the rollers to work. Actually, without the presence of the shaft, it is difficult and almost impossible for the rollers to work. So, in fact, it can be considered as the constant helper of this industrial element. But another part in the rollers is the bearing. Bearings are responsible for maintaining the connection between the shaft and the main body. So don’t forget that all three of these elements can form a very useful system by being together.

Types of rollers

steel

Steel rollers are usually the strongest and most durable type of roller. They are used for heavy duty applications such as power transmission or moving heavy materials. You have definitely seen this type of roller. One of the common misuses of this is in the field of road and street construction. You have seen a car with a big roller on the front moving on wet asphalt and smoothing it.

plastic

Plastic rollers are usually lighter and cheaper than steel rollers. They are used for light applications such as smoothing surfaces or manufacturing products. Usually these rollers are not used heavily. Why? Because they may not have the ability and resistance. Of course, this does not mean that their gender is weak. These rollers are made of compressed plastic.

rubber

Rubber rollers are usually the most flexible type of roller. They are used for applications such as smoothing rough surfaces or manufacturing products. What is meant by producing products? Products that are close to the roller type. such as belts, etc.

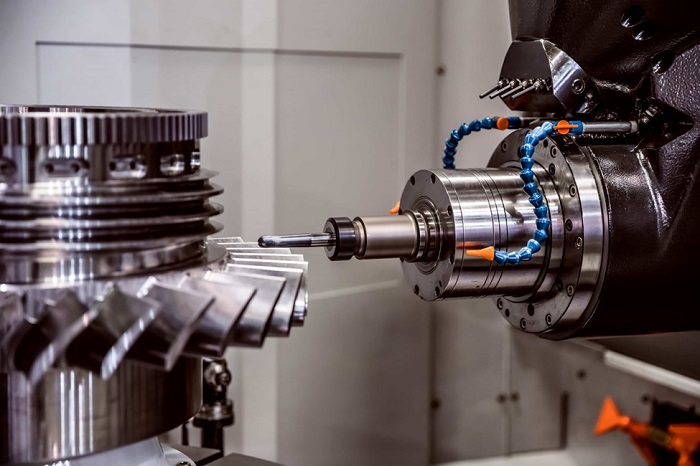

industrial

Industrial rollers are commonly used for industrial applications such as product manufacturing or construction. They are usually made of durable materials such as steel or compressed and reinforced plastic. Industrial rollers are also used in industries such as road construction, which we mentioned a while ago.

agriculture

Agricultural rollers are commonly used for agricultural applications such as crop production or harvesting. They are usually made of durable materials such as steel or plastic. These rollers are used to level the land for the next crops. Also, sometimes they are used to pound agricultural products.

Types of roller covers

The cylindrical body of the rollers needs to have a coating. This coating is different according to the application that this system should have. Rubber and polyurethane coatings are mainly used on these cylinders. These two elements may have similarities to each other, but they also have differences. For example, rubber coating should be used when we need softness and flexibility. But this is not the case when using polyurethane coating. When using polyurethane coating, it should be noted that this element is made for industrial and heavy work. So, note that the cover material can be different according to the application. Therefore, in activities such as polishing and grinding, sandblasted coatings are also used.

Roller applications

These elements are used in a wide range of industries. Now these industries can be scientific or vital or even everyday industries. For example, you may see these parts in department stores. You may see the use of these elements in welding and turning workshops. They also have many applications in various other industries. Industries such as medical industries, electronics industries, petrochemical and oil and gas industries, automotive industries and even construction industries. In these fields that we said, rollers can be used to transfer power and products. Also, in some others, these rollers are used to smooth and polish the surface of objects. So don’t forget that the use of these elements can include a huge range of industries and activities.

Thank you for following us to the end of this article. As you have seen, in this article we reviewed and introduced rollers and their types. You also saw that we examined its types and its important benefits. But it is not bad to say once again that these elements are used to transfer power, transfer materials and objects, smooth and polish the surface of objects, etc. Mabanapaya Industrial Group, with expertise in the production and repair of all kinds of rollers, is ready to provide you with the necessary assistance in this field. Mabanapaya Industrial Group, having the ISO 9001 certificate, is proud to announce that it is ready to manufacture and repair all kinds of rollers. Dear friends, you can contact the consultants and experts of Mabanapaya collection to get more information and get free advice. Thank you for your cooperation.