We know that with the growing trend that the world’s population is facing, along with it, technology is also progressing and undergoing many changes. Today, many tools are used in various industries to obtain newer and more up-to-date parts and technologies. Definitely, the use of these tools and technologies is for the well-being of people’s lives. In any industrial or production workshop, sandpaper is one of the essential tools that are used in different stages of production, from the preparation of parts to the final finishing. Sandpaper uses abrasive grains to smooth, polish or shape different surfaces. Today, the use of this tool is very common in industrial units. Today, in this article, we are going to introduce different types of sandpaper. So accompany us to the end.

What is the sandpaper?

It is a flat sheet or plate on which abrasive grains are glued uniformly. Abrasive grains can be made of different materials such as aluminum oxide, silica, corundum or diamond. Note that each model of sandpaper is used in different activities. As a result, this means that one sanding model cannot be used to smooth and polish different surfaces. Also, according to the level of resistance, roughness and ingredients, sandpapers can be divided into different types, which we will discuss later. Stay with us to provide you with more information about this tool.

Advantages of sandpaper

Sandpaper is used to prepare parts before further operations such as welding, painting or finishing. At this stage, sandpaper is used to remove roughness, waste and pleats on the surface of the piece.

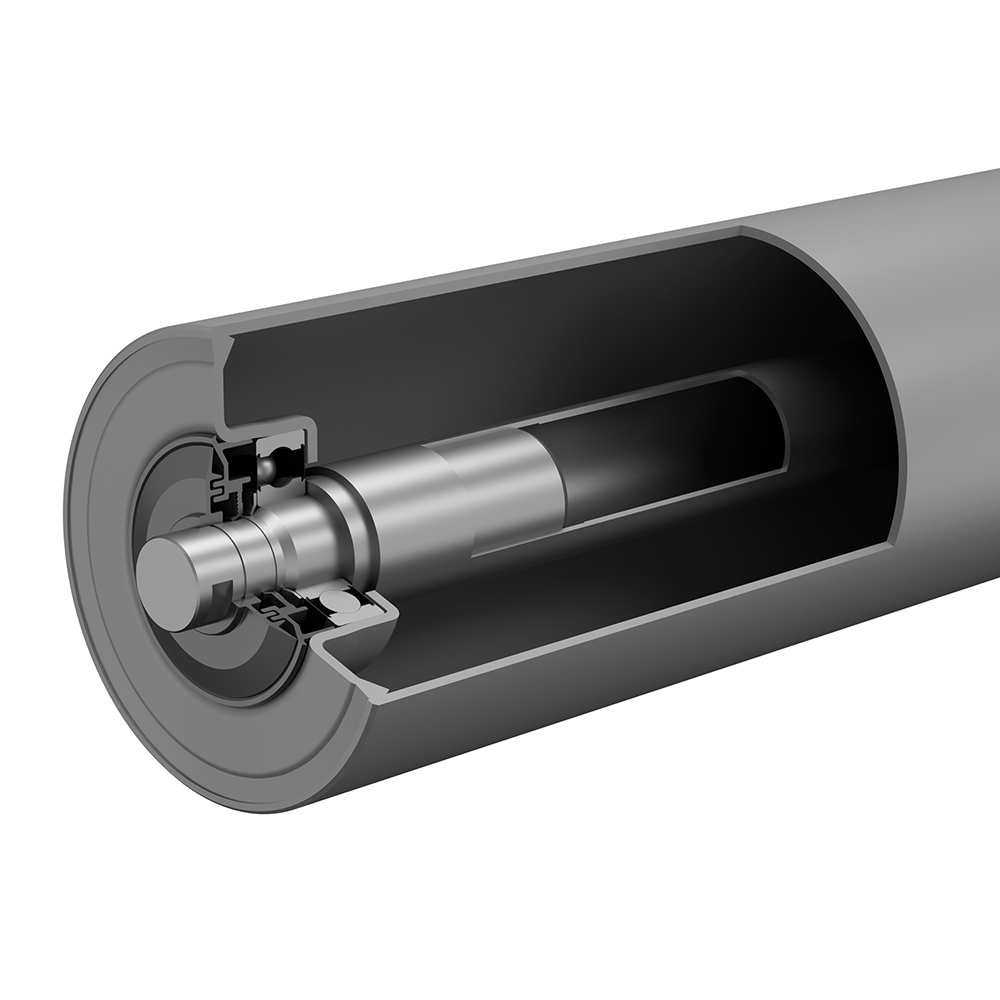

Nowadays, grinding has become one of the most used activities for making different parts, especially metal parts. Sandpaper is one of the main grinding tools. In grinding, the sandpaper rotates around an axis and brings different surfaces to the desired shape and size.

You may ask, what does polishing mean? In fact, here the meaning of polishing is roller polishing, in which we can have smooth and polished surfaces by using rollers. Now you may ask what is the role of sanding? Sometimes it is possible to use sandpaper as a coating of the roller. Sandpaper is used for finishing the parts and creating a smooth and polished surface.

Advantages of using sandpaper when working with industrial parts

Today, different industries and of course different industrial parts form a very large part of our lives. You know that various parts are produced, including metal parts, rubber parts, polyurethane parts, etc. In connection with metal parts, the use of sandpaper is more common. Using sandpaper has many advantages when working with industrial parts. Among the advantages of using sandpapers, the following can be mentioned:

Polishing surfaces

Nowadays, it is necessary to use accurate and smooth parts in various industrial activities. But how can we get such parts? This element can completely smooth and polish different surfaces. This increases the beauty and durability of the parts.

Remove waste

Sometimes the appendages on the surface of the metal parts may cause damage to the devices. It may also cause parts to not fit together well. Sanding can remove roughness, waste and pleats on the surface of the piece. This increases the accuracy and performance of the parts.

Shaping surfaces

You must have seen that sometimes you may want to give certain shapes to metal parts. But sometimes you may not have the necessary devices for it. Sandpaper can shape different surfaces into the desired shape and size. This increases the efficiency and performance of the parts.

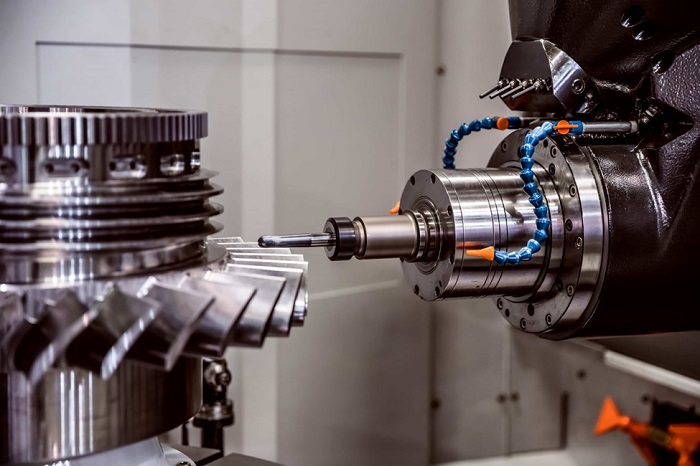

Grinding and sandpaper role in it

We said that today grinding has become one of the main and most important activities in industrial units. Grinding is a specialized activity in which it is tried to clean the surface of the parts from excess impurities and deliver a smooth and polished part by using special sandpapers and grinding wheels. We said that grinding is one of the important processes in various industries, which is used to shape different surfaces. In grinding, by rotating around an axis, sandpapers bring different surfaces to the desired shape and size. Sandpapers play an important role in grinding, and the quality of grinding largely depends on the quality of the sandpaper. Sandpaper should have proper graining, proper adhesion and sufficient resistance to wear. Mabnapaya Industrial Group specializes in the field of grinding parts.

The best sandpaper

pulpy

It is one of the most common types of sandpaper, which is made of a sheet of paper or cardboard coated with abrasive grains. It is produced in different types of granularity and size. Today, this model of sandpaper is known as the most common type of this element. You have definitely seen them a lot. These crimson colored tools are available in the market and are widely used.

sponge

This model is made of a layer of sponge coated with abrasive grains. Sponge sandpaper is more flexible than paper sandpaper and is suitable for curved and uneven surfaces. Remember we said that any type of sandpaper is suitable for an activity. Here we can reach the conclusion of that word.

Strip

As the name suggests, it is made of a thin strip coated with abrasive grains. Belt sanding is suitable for large and wide surfaces. So, if you need to polish a series of large and huge surfaces, using this element is recommended.

Disc

But this model is also one of the most widely used in various industries, especially in grinding workshops. This element is made of a disc coated with abrasive grains. This product is suitable for use with grinding machines, and if you intend to do this, you need to take advantage of it.

circular

This model is another sandpaper used for grinding. If you intend to do bigger activities in grinding, using this model is recommended. A wheel sander is made of a wheel coated with abrasive grains and is suitable for use with grinding machines.

Choosing the right model of sandpaper for grinding

Choosing the right sandpaper model for grinding depends on various factors such as the type of part, the shape of the part, the grinding operation and the required accuracy. In the following, we will examine these factors:

The type of part is one of the most important factors in choosing the right sanding model. For example, for grinding metal parts, aluminum oxide or crond sandpapers are used. Silica or diamond sandpapers are used for grinding wooden parts.

The shape of the piece also plays a role in choosing the right sanding model. For example, sponge or belt sanders are used for grinding curved and uneven parts. Belt or disc sanders are used for grinding large and wide parts.

Grinding operation also plays a role in choosing the right sanding model. For example, coarse-grained sandpapers are used for initial grinding operations. For the final grinding operation, fine-grained sandpaper is used.

The required accuracy also plays a role in choosing the right sanding model. Fine-grained sandpaper is used for high-precision grinding operations.

Thank you for accompanying us to the end. We said that sandpapers are one of the essential tools in various industries that are used in different stages of production, from the preparation of parts to the final finishing. Sandpapers use abrasive grains to smooth, polish or shape different surfaces. Choosing the right sandpaper model for grinding depends on various factors such as the type of part, the shape of the part, the grinding operation and the required accuracy. By choosing the correct sanding model, it is possible to improve the grinding quality and prevent damage to the parts. Mabnapaya Industrial Group, an expert in the field of roller grinding and polishing, is ready to start cooperation with industrial units. You can contact us for more information.