As time passes, many advancements are made in various industries. These developments make humans need to use new tools. These tools should be such that they can be used in a huge range of industries. Different parts are made of different materials. The most used parts in the world today are metal parts. But you have to think of a plan to protect these parts well. One of the ways to protect metal parts is to use coatings. Coatings are one of the important components in many industrial and commercial equipment. They are responsible for protecting the surface against wear, corrosion and damage. Rubber coating and polyurethane are two common types of coating that are used in different applications. In this article, we are going to examine the difference between these two elements.

Rubber coating

At first, it is better to introduce you to the rubber coating. It is a synthetic material that is made from a combination of natural and synthetic materials. Rubber has various properties that make it suitable for use as a coating in various applications. Rubber coating has many properties, including flexibility, resistance to wear, resistance to temperature changes and resistance to chemicals. The fact that tires have these properties has caused these elements to be used in various industries such as automobile manufacturing, construction, etc.

Polyurethane coating

Now let’s get to know polyurethane together. Polyurethane is a synthetic polymer that is formed by the reaction between two chemicals called isocyanate and polyol. This product is made from a combination of organic and inorganic materials. Polyurethane has various properties that make it suitable for use as a coating in various applications. The properties of polyurethane are not so different from the properties of tires. Among the features that these products have are resistance to high temperature, resistance to wear and corrosion, and resistance to corrosive and dangerous chemicals. These features make polyurethane coating a serious competitor for rubber coating.

Which coating is better?

The choice between rubber coating and polyurethane coating depends on many factors, including environmental conditions, intended application and budget. In fact, polyurethane coating has a higher resistance to wear, temperature and chemicals. This makes polyurethane coating a better choice for applications that require high strength, such as industrial rollers and conveyor belts. However, rubber coating is more flexible and costs less. This makes rubber coating a better choice for applications that require flexibility and low cost, such as wheels and bases. But this question may arise for many of you, when should we use polyurethane coating? You may also ask when should we use a rubber coating? Do not hurry. We will answer all these questions.

When should we use rubber coating?

It is natural that the use of rubber coating should be done in special conditions. In the following, we will check together when we should use this coating. Due to their properties, these coatings are best used in conditions that require high flexibility. Also, due to their more reasonable price, they are used when we think of saving money. Plastics show high resistance to temperature changes as well as harmful chemicals. So it is recommended to use rubber coating when parts may be exposed to such conditions.

When should we use polyurethane coating?

But just as rubber covers should be used under special conditions, polyurethane covers should also be used in special cases. We said that polyurethane coatings can be highly resistant to wear and corrosion. Therefore, in industries where parts may be more exposed to damage, we should use polyurethane coating. Also, these coatings show high ability in high temperature and in dealing with chemicals. Therefore, polyurethane coating can be used when parts are exposed to temperature damage caused by chemicals.

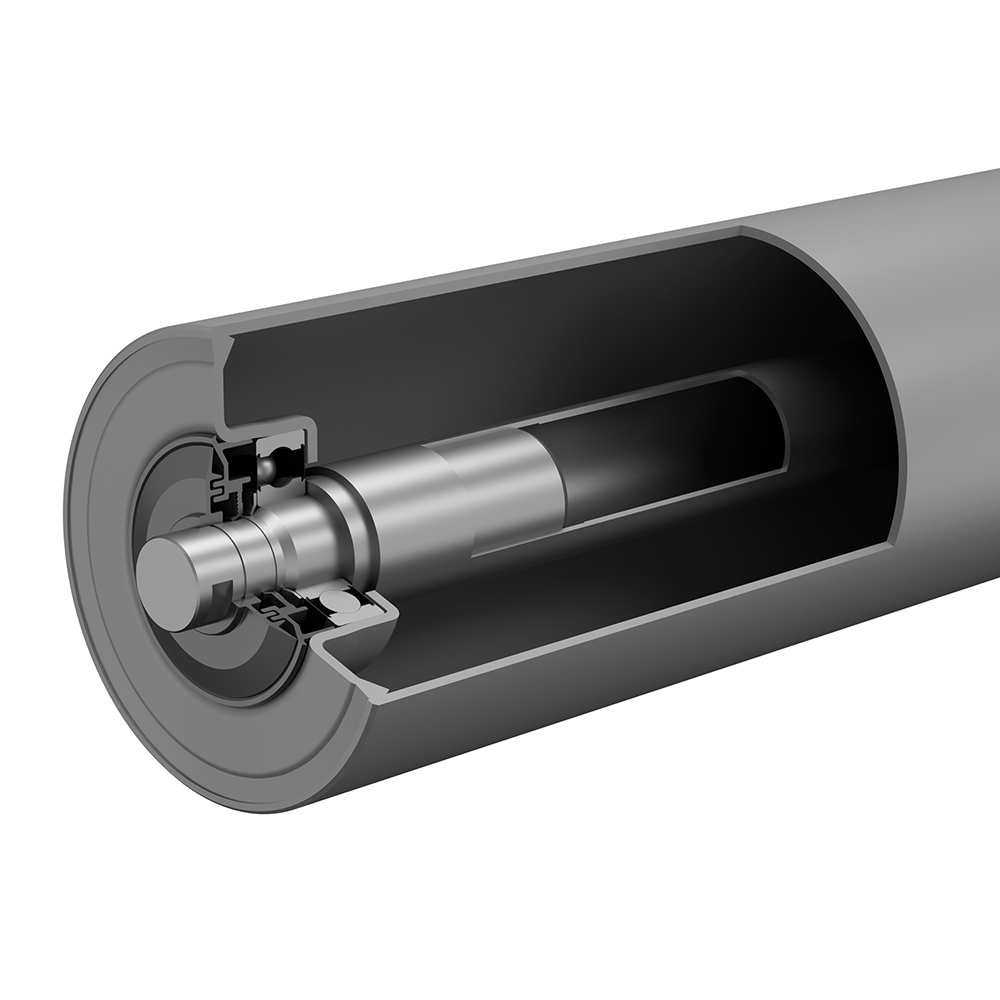

Use of rubber and polyurethane coating on the rollers

First, let’s say what is a roller? Although you may know it. Rollers are hollow cylinders that consist of a body, shaft and bearing and have many uses. Rollers are one of the important components in many industrial equipment. They are used to transport materials, products and parts in the production line. Rollers are subject to wear, corrosion and damage. Both rubber and polyurethane coating are suitable options for roller coating. They have good resistance to wear, corrosion and damage. However, polyurethane coating has higher wear and temperature resistance. This makes polyurethane coating a better option for rollers that are exposed to high wear and high temperatures. Here are some examples of rubber and polyurethane coating applications on rollers:

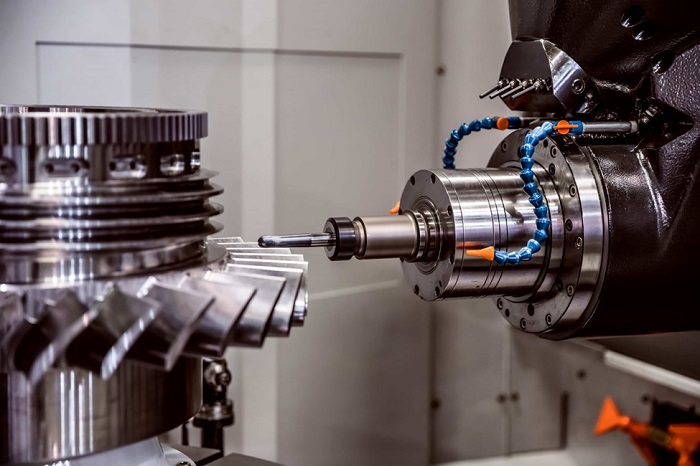

Industrial rollers

Rubber and polyurethane coatings are used to protect industrial rollers against wear, corrosion and damage. These rollers are used in various industries including production, packaging and transportation. Due to the heavy work of these rollers, they should be handled a lot.

Printing rollers

Due to their properties, these coatings are used to protect printing rollers against wear, corrosion and damage. These rollers are used in printing and packaging industries and because they have to work continuously, it is necessary to pay attention to their health.

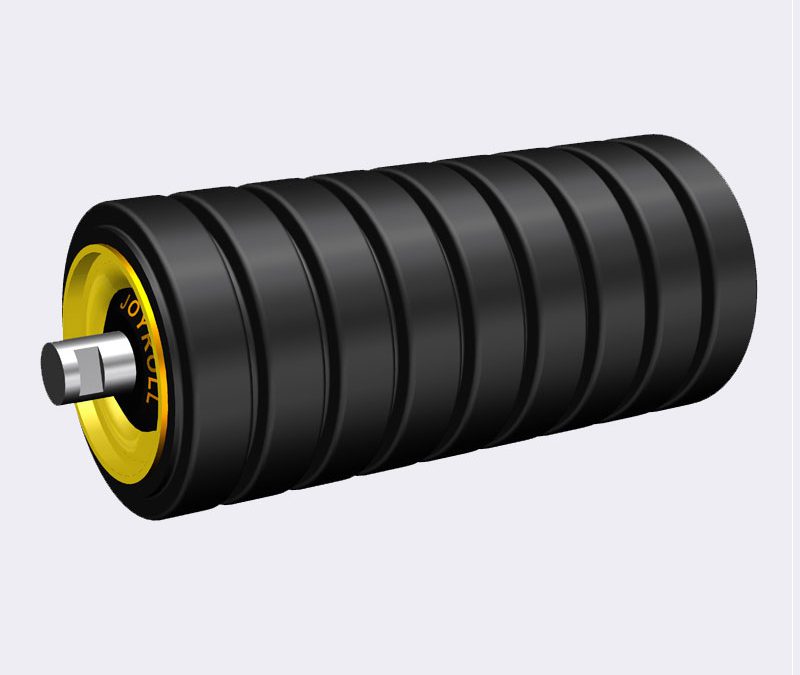

Conveyor rollers

Polyurethane and rubber coating are used to protect the conveyor rollers from possible damage. These rollers are used in various industries including manufacturing, packaging and retail. Considering the efficiency required in these industries, quality materials should be used.

The price of rubber coating and polyurethane coating

It can be said that we have answered all the questions related to the differences between these two covers. Except for one question related to the cost of these covers. Of course, in general, a price cannot be considered for these two elements. The price of rubber and polyurethane coating depends on various factors, including the type of coating, thickness of the coating, hardness of the coating and size of the coating. In general, rubber coating is cheaper than polyurethane coating. You should also know that the plastic cover and simple polyurethane have a lower price than the anti-wear type. We should choose the cover according to your type of activity. You can buy the best cover at the best price by using the advice of Mabnapaya experts.

Thank you for joining us in this article. You saw that in this article we examined the differences between rubber coating and polyurethane coating. We also said which coating is better to use in different situations. Both rubber and polyurethane coatings are suitable options for protecting industrial equipment against wear, corrosion and damage. The choice between these two types of coatings depends on a variety of factors, including environmental conditions, intended use, and budget. There are several factors to consider when choosing the right cover. By considering your specific needs, you can choose the best type of coating for your application. With the ISO 9001 certificate, Mabanapaya Industrial Group is ready to provide you with the best coatings. For more information, please contact us.