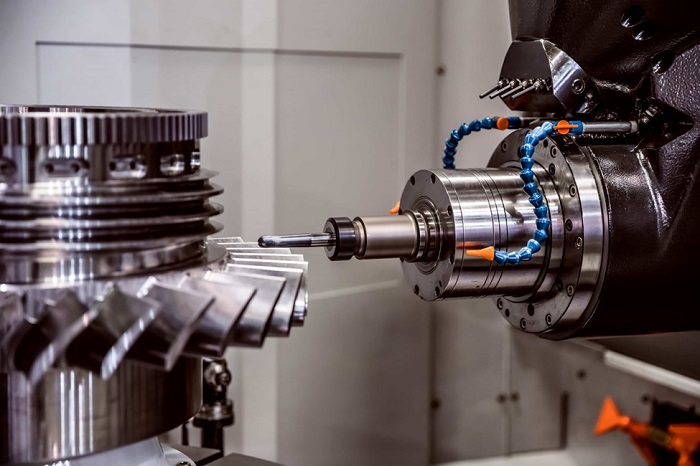

With the passage of time and the advancement of technology, new parts are made every day to help humanity. Knowing that the world’s natural materials will one day end, the people of the world are always trying to make replacement parts and materials. This will make people live a better life in the future. without worrying about running out of resources. But what did we say these things to achieve? Two materials have been created in the world whose properties are relatively similar to each other. Rubber and silicone are two elastomer materials that have many applications in various industries. These two materials have differences in terms of physical and chemical properties, which makes them suitable for different applications. Today, in this article, we are going to introduce silicone and rubber parts and the differences between them.

Silicone parts

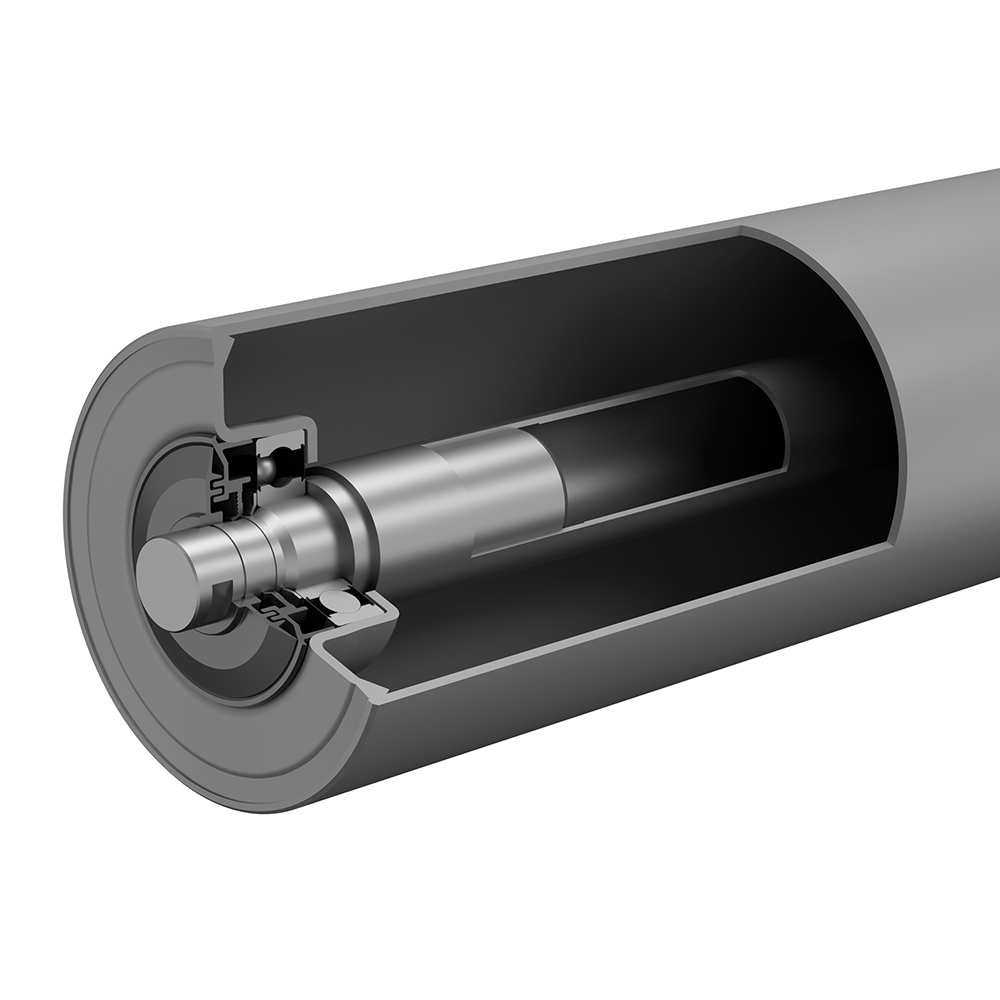

Silicone parts are made of silicone material. This is an elastomer material that is made from the combination of silicon dioxide and carbon. Silicon is a natural substance that is abundantly found in nature. Silicone parts have many advantages that make them widely used in various industries. Among the advantages of silicone, the following can be mentioned:

- Heat resistance

- Resistant to chemicals

- Waterproof and moisture-proof

- Anti-bacterial and anti-fungal

- Radiation resistance

Applications of silicone parts

Silicone parts are used in various industries such as food industry, pharmaceutical industry, electronic industry and medical industry. They are used in the food industry to produce dinnerware, molds and washers. Silicone parts are used in the pharmaceutical industry to produce medical equipment such as pumps, catheters and caps. These parts are used in the electronics industry to produce electronic parts such as printed circuits, protectors and connectors. Silicone parts are used in the medical industry to produce medical equipment such as body prostheses, implants and orthodontics.

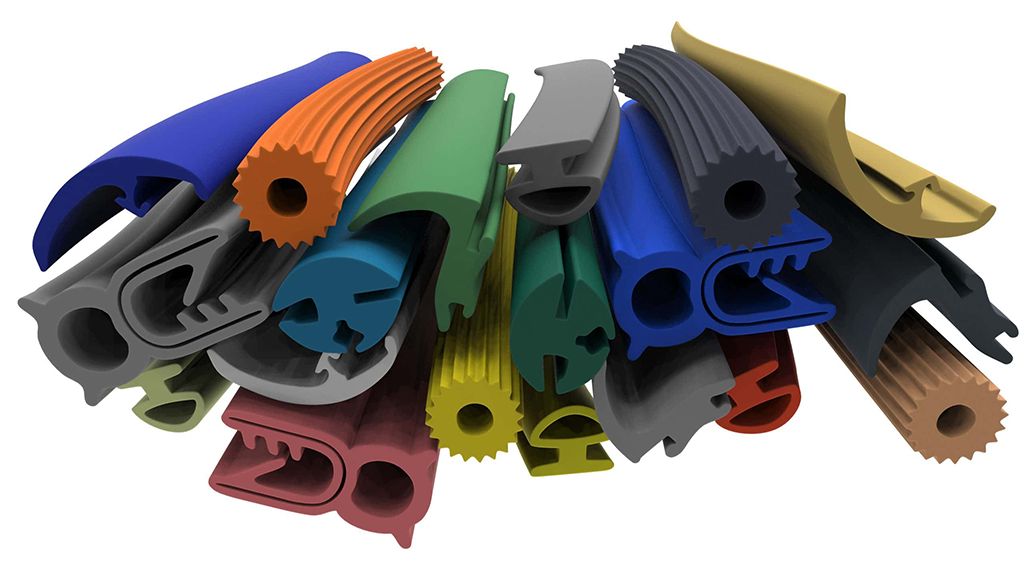

Rubber parts

Rubber parts are made of rubber material. It is an elastomeric material that is made from a combination of latex, additives and reinforcing materials. Latex is the main component of rubber, which is obtained from the sap of rubber trees. Additives such as paint, oil and sunscreen are added to improve the properties of rubber. Reinforcing materials such as carbon black, cloth and glass fibers are added to increase the resistance and strength of rubber. Rubber parts have many advantages that make them widely used in various industries. Among the advantages of rubber parts, the following can be mentioned:

- Resistance to wear and corrosion

- flexibility

- Impact resistance

- Waterproof and moisture-proof

- Electrical insulation

Applications of rubber parts

Rubber parts are used in various industries such as automotive, construction, electronics and medicine. Rubber parts are used in the production of car parts such as car tires, water pumps, hoses and washers. They are used in construction to produce insulators, sealants and joints. These parts are used in electronics to produce electronic parts such as wires, cables and covers. Rubber parts are used in medicine to produce medical equipment such as gloves, syringes and tubes.

The difference between rubber and silicone parts

Rubber and silicone parts have different physical and chemical properties that make them suitable for different applications. Let’s explore the differences between these two elements in the following features.

Silicone parts are more resistant to heat than rubber parts. Silicone parts withstand temperatures up to 200°C, while rubber parts withstand temperatures up to 100°C.

Silicone parts are more resistant to chemicals than rubber parts. Silicone parts are resistant to most chemicals, including acids, bases, and solvents, while rubber parts are less resistant to some chemicals, such as strong acids and strong bases.

Silicones are naturally waterproof and moisture-proof, while rubber parts are not naturally waterproof and moisture-proof. Rubber parts must be made with waterproof and moisture-proof additives to have these properties.

We checked earlier that this is one of the main characteristics of silicones. While rubber parts are not naturally anti-bacterial and anti-fungal. Rubber parts must be made with antibacterial and antifungal additives to have these properties.

We said that silicone is more resistant to UV rays than rubber parts. Silicone parts do not discolor or crack when exposed to UV light, while rubber parts do discolor and crack when exposed to UV light.

Rubber parts are more flexible than silicone parts. Rubber parts can easily stretch and return to their original shape, while silicones are less flexible. Elasticity is one of the prominent characteristics of tires.

Rubber and silicone parts have good resistance to wear and corrosion. However, according to the tests conducted by scientists, in the same conditions, rubber parts show more resistance.

The price of an element is always the most important point for the owners of industrial units. Rubber parts are usually cheaper than silicone parts.

Which piece is better?

It is impossible to say which one is better without considering the circumstances. The choice of rubber or silicone parts depends on various factors such as environmental conditions, application of the part and budget. If the part in question must be exposed to high temperatures, chemicals, water and humidity, ultraviolet rays or bacteria and fungi, it is better to use silicone parts. But if the part in question must have a lot of flexibility, it is better to use rubber parts. If the desired part must be cheap, it is better to use rubber parts. So you should consider all the available conditions before choosing the desired piece. Then prepare the piece. The consultants of Mabanapaya Industrial Group are ready to provide you with the necessary tips for free.

Thanks for sticking with us until the end. You saw that in this article we have thoroughly reviewed rubber and silicone parts. We also examined the features of both elements together and finally came to the conclusion that which one can be a more suitable option to use. It is not bad to say again that in order to choose the right part, it is necessary to consider the conditions completely. It is also necessary to take advantage of the help of an expert in this field. We at Mabanapaya Industrial Group, having the ISO 9001 technical certificate, are ready to provide you with the necessary assistance. If you want to receive free advice or place an order, you can contact the experts and specialists of Mabanapaya Industrial Group. We hope that the material presented in this article will be useful for you. follow us.