Static roller balance

Static balance of the roller is a process in which the mass of the roller is distributed in such a way that the centrifugal force is zero at any point of the roller.

In today’s industrial world, rollers play an essential role in many processes and machines. Rollers are used in various industries including food, textile, printing, packaging, electronics and automobile manufacturing. Rollers are cylindrical shaped parts that are used to transfer force or material. They can be made of different materials such as metal, plastic, or wood. With these interpretations, we can conclude that paying attention to the health and proper functioning of the rollers is a vital issue in advancing the activities we mentioned. Static roller balancing is one of the most important processes to ensure the correct operation of the rollers. Today, in this article, we are going to examine the static roller balance process. If you are also interested in this topic and need it, accompany us to the end.

What is a roller and what are its uses?

In general, rollers are cylindrical shaped parts that are used to transmit force or material. They can be made of different materials such as metal, plastic or wood. Great care must be taken in making these parts because the smallest error in its operation can cause many losses. But what is the use of these elements? Rollers are used in many fields. In the food industry, rollers are used to transport food materials such as dough, paper and other elements. In the textile industry, rollers are used to straighten and stretch fabrics. In the printing industry, rollers are used to transfer ink to paper. It can also be said that they play a role in stabilizing the ink as well as possible. In the packaging industry, rollers help to pack products. In the automobile manufacturing industry, rollers are used to transport automobile parts. These parts are also widely used in the electronic industry.

What is static roller balance?

Static balance of the roller is a process in which the mass of the roller is distributed in such a way that the centrifugal force is zero at any point of the roller. This is done by adding or subtracting weight from different points of the roller. Static roller balancing is essential to ensure the correct operation of the rollers. Using unbalanced rollers can cause vibration, wear and damage in machinery. Note that the occurrence of these cases can cause a lot of costs. So it is necessary to pay a lot of attention to the static balance of the rollers.

What does static and dynamic mean?

Maybe this question will arise for you, what does the word static mean? First, we must say that the static state is the opposite of the dynamic state. Static means a state in which the object is not moving. Dynamics is a state in which the object is moving. In static balance, the roller is at rest. In dynamic balance, the roller is rotating. The specialized activity of Mabnapaya collection is based on static roller balance. This makes it more accurate when balancing the roller. The result is the correct and error-free operation of the roller.

Advantages of roller balance

We said that the balance of the roller can cause the roller to work correctly. Among the benefits of the roller being balanced, the following can be mentioned:

- Vibration reduction

- Reduction of wear and breakdown in machinery

- Increasing the useful life of machinery

- Increasing the quality of products

- Reducing production costs

Disadvantages of roller imbalance

Just as the roller balance had many advantages, the lack of roller balance also includes disadvantages. Improper and unprincipled activity of the roller can cause the following:

- successive vibrations of the roller

- Increased wear and tear of machines

- Reducing the quality of products

- Destruction and reduction of useful life of machinery

- Causing consecutive financial losses due to numerous breakdowns and increased production costs

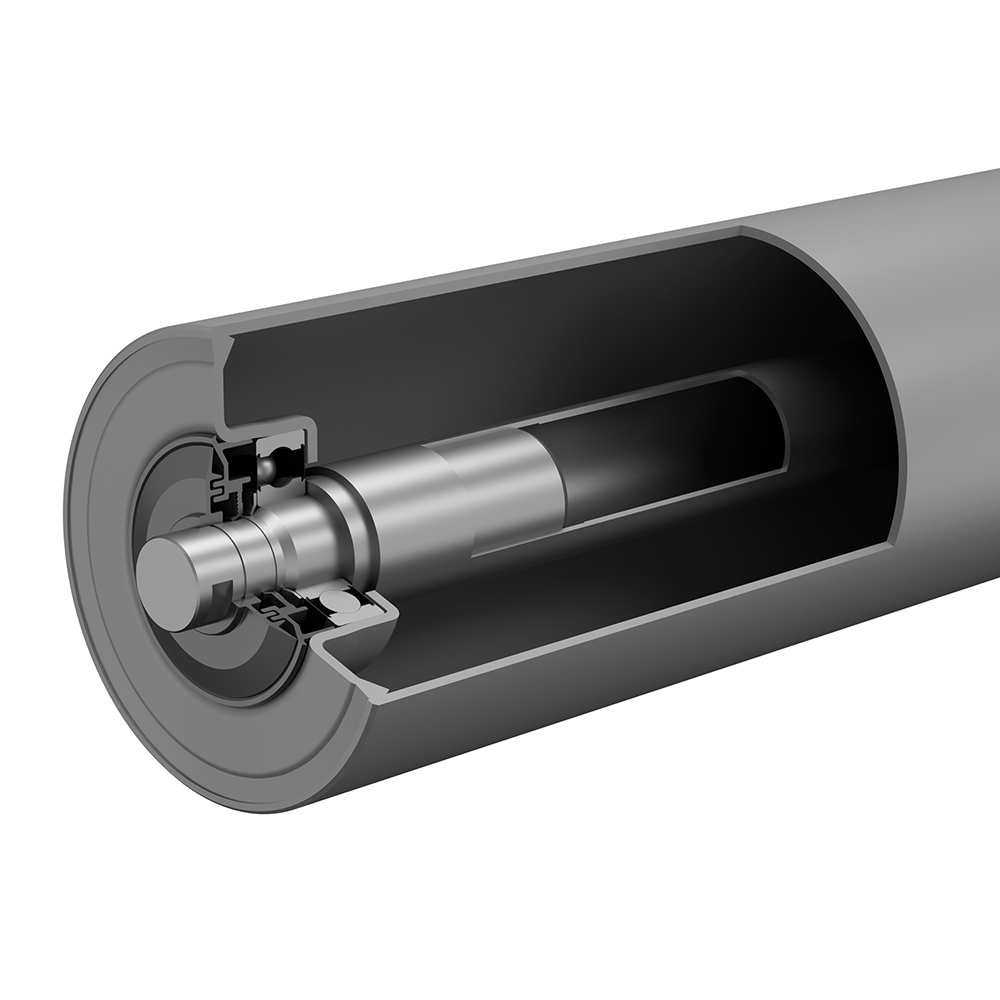

Roller static balancing process

The static balance of the roller is generally done using static balance devices. These devices have a vertical axis on which the roller is placed. Static balancers have a set of sensors that measure torque and centrifugal force at different points on the roller. The roller static balancing process is as follows:

1- The roller is placed on the axis of the static balance device.

2- The static balance device measures torque and centrifugal force at different points of the roller.

3- The location of the roller imbalance is determined using the data measured by the balance device.

4- Appropriate weight is added or subtracted in the place of roller imbalance.

5- The static balance process is repeated until the balance of the roller reaches a completely acceptable value.

Static balance devices

The roller balancing process is not done statically by only one type of device. As a result, it is done by different types of devices. There are different types of static balance devices. Some of the most common types of static balance devices are:

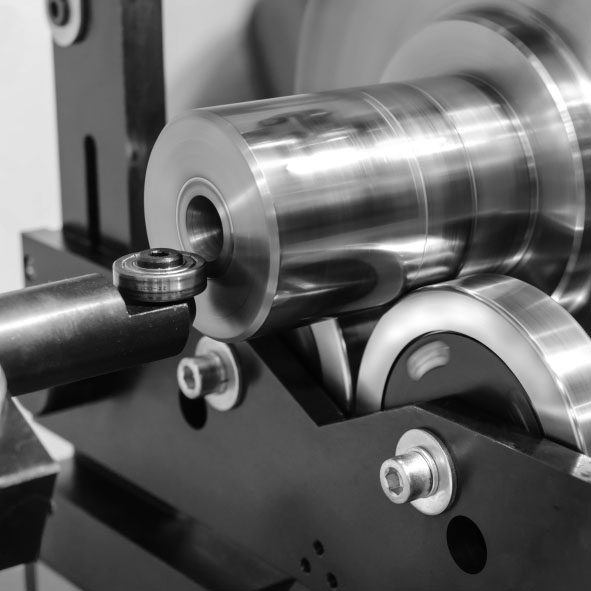

Manual static balance devices

These devices can be introduced as the most widely used and at the same time the most traditional type of roller balance devices. Maybe it is clear from its name how it works. These devices are small and portable and are suitable for balancing small rollers. By placing the rollers on this device, they are ready for the balancing process. It is necessary to repeat that this device is used for balancing small rollers.

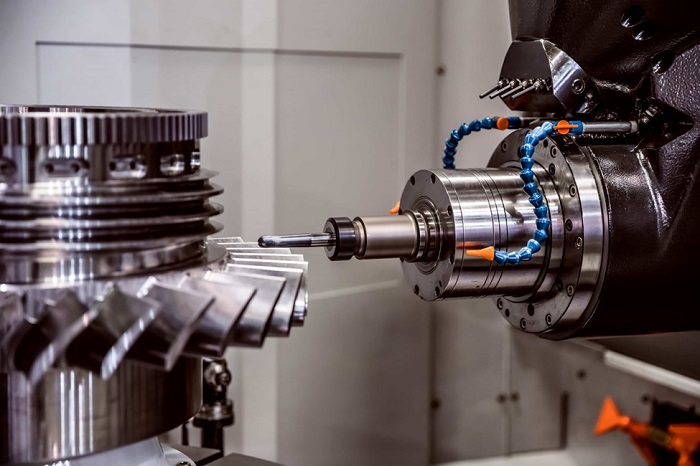

Computerized static balance devices

But now let’s talk about another type of static roller balance devices that are widely used today. These devices have a built-in computer that processes the measured data and determines the location of the roller imbalance. It is worth noting that the precision made in the final result of the work is more than the manual balance machine. Also, these devices can be used to balance large and huge rollers.

Safety tips during static roller balancing

We know that many accidents can happen in the industry. This is especially true in heavy and machine industries. Static roller balancing is also a process that can be dangerous. Therefore, it is necessary to observe safety tips to prevent accidents. Some of these safety tips include:

Use of safety equipment including gloves, safety glasses, and safety shoes.

Ensuring the correct operation of the roller static balancer. You should check this before starting work.

Avoid putting your hands or fingers in the path of the roller. The weight of huge ghatlaqs may cause irreparable accidents.

Be sure to work as a group when statically balancing huge rollers. Group activity makes the pressure on people divided and the work goes more correctly.

Signs of the roller needing balance

Now, you might ask, when do we know a roller needs balancing? First of all, we must say that people who work in jobs related to the use of rollers, using their experiences, quickly and easily realize the need for balance repairs. But apart from these explanations, there are signs that, by observing them, you will realize that your roller should go through the balancing process as soon as possible. In the following, we will examine some of the most common and main symptoms.

It can cause the weight of the roller to change at different points. This issue causes disruption in the work of the roller and reduces its efficiency. Reducing the efficiency of the roller only causes a waste of energy, cost and time and causes a lot of damage to the quality.

It can cause the roller to break or crack. These fractures can enter the inner and outer parts of the roller, as well as the roller shaft, which is placed on its side. The roller shaft is one of the main parts that helps the continuous activity of the roller.

A change in the material of the roller can cause a change in its mass and mass distribution. This change can be done in different parts. such as roller body, roller shaft and bearings. Also, the repairs that are done can also cause this damage. The main repair that causes this to happen is the repair of the bearing, which can happen as a result of welding.

Thank you for joining us in this article. As you have seen, in this article, we examined the static balance of the roller. Static roller balance is one of the most important activities that can increase the life of rollers. Keep in mind that rollers need more care because they are used continuously for hours on a daily basis. Servicing the parts of the rollers as well as the static balance of the rollers can help the activities you do with this device to be done completely and correctly. Therefore, regular static balancing of the rollers is necessary. Having ISO 9001 certificate in quality management system, Mabanapaya Group is ready to help you in the field of static lifting of all kinds of rollers. You can contact the experts of Mabanapaya collection to get more information and get free advice.