Rubber roller

Rubber roller is made of rubber and have several advantages over other rollers. Like other roller models, this roller model can be used in different industries.

If you also have a small expertise in various industries, you know the importance of rollers in various industries. These objects can be made and used with different materials. Each type of roller is made for a specific activity. Rubber rollers are one of the most widely used rollers in the industry. Rubber rollers are one of the most important industrial equipments that are used in a wide range of industries. These rollers play an important role in transferring materials, transferring power and performing various industrial operations. This model of roller has advantages over other types of rollers. But don’t rush. We will cover everything you can think of. Today, in this article, we are going to review and introduce rubber rollers. So don’t miss this article and stay with us till the end.

What is a roller?

First, it is better to answer the question, what is a roller? A roller is an industrial part that usually consists of a hollow cylinder. Rollers can be made of various materials such as metal, rubber, plastic and wood. Rollers are used to transfer materials, transfer power and perform various industrial operations. For example, rollers are used to transfer materials on conveyors, transmit power in industrial machinery, and perform various operations in the printing and packaging industries. Rollers can be divided into different types based on material, shape and application.

Based on gender

Metal

Rubber

Plastic

wooden

Based on the figure

simple

grooved

toothed

Banded

Based on application

Industrial roller

Agricultural roller

printing roller

Packing roller

What is a rubber roller?

Now it’s time to examine the main issue. What we wanted to introduce and examine from the beginning of the article. What is a rubber roller? Rubber rollers are one of the most widely used types of rollers. Rubber rollers are made of rubber and have several advantages over other rollers. Like other roller models, this roller model can be used in different industries. Of course, according to the type of activity, the amount of resistance and the weight of the roller should be determined. If you plan to use rubber rollers in heavy industries, it is better to use large rubber rollers. Otherwise, you can use lighter rubber rollers. Rubber rollers also have advantages that we will examine below.

Advantages of rubber rollers

Rubber rollers are more resistant to wear than other rollers. This makes the rubber rollers last longer and require less maintenance. This issue causes the costs imposed on industrial units to decrease.

These rollers are more resistant to corrosion than other rollers. This makes rubber rollers usable in corrosive environments. As a result, the scope of their use increases.

Rubber rollers are elastic and can absorb vibrations. This feature is not present in many other rollers such as wooden and metal ones. This makes rubber rollers to be used in environments where there is a need to reduce vibrations.

In fact, it can be said that this flexibility comes back to the same elastic feature. Rubber rollers are flexible and can withstand different forces. This makes rubber rollers very useful in environments where there is a need to withstand different forces.

The presence of friction in the working process of any element can help reduce its lifespan. This is not good at all. This kind of cost is imposed on the owners of industrial units. Rubber rollers have a low friction coefficient. This makes rubber rollers to be used in environments where there is a need to reduce friction.

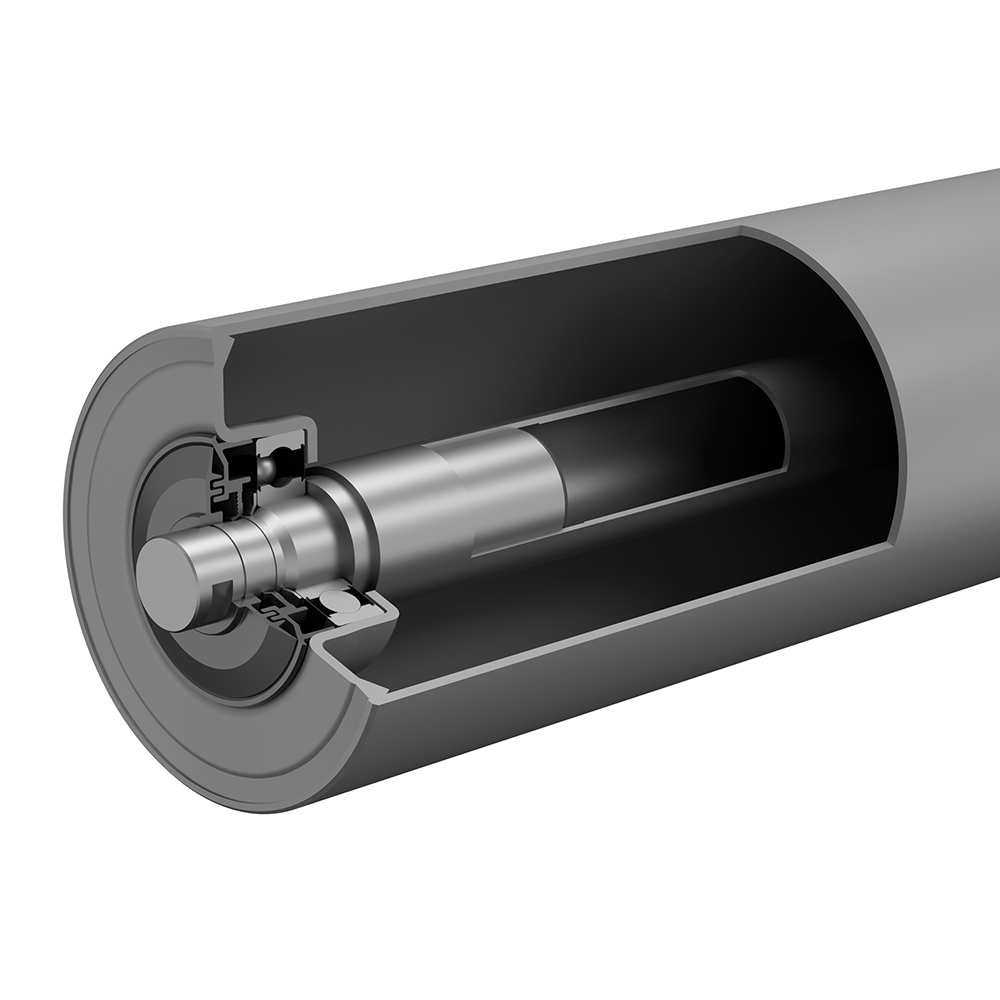

Components of rubber rollers

It doesn’t matter if your roller is wooden, metal, plastic or rubber. However, there are components in rollers that are common to all rollers. You may ask what are the names of these parts and what are they for? Shaft and bearing are important components of rubber rollers. The shaft forms the axis of the roller and the bearing holds the shaft in place. Rubber roller shafts are usually made of steel. Rubber roller bearings are also usually made of steel, brass or polymer. By saying these points, you may have realized that these two parts have a significant effect on the positive performance of the roller. It is worth noting that any failure in these two parts can cause the roller’s performance to be disturbed in general.

The importance of rubber rollers in different industries

Rubber rollers are one of the most important industrial equipments that are used in a wide range of industries. We said that rollers play an important role in transferring materials, transferring power and performing various industrial operations. In the rest of the article and in this section, we are going to examine the importance of this industrial element in different industries. Stay with us.

building industry

In industries such as the construction industry, rubber rollers are used to transport materials in construction conveyors, transmit power in construction machinery, and perform various operations in the construction industry. For example, rubber rollers are used in cement and construction material transfer conveyors, in concrete pouring machines, and in stone and tile cutting machines. To prove it, let us give you an example. Imagine that you are going to move heavy elements to the upper parts of the building. This can be very difficult to do manually, but with a roller there is no pressure on the workers.

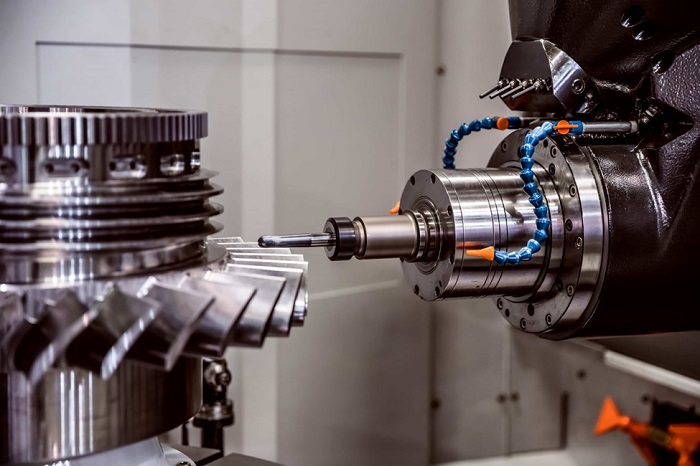

The automotive industry

This industry is one of the most important industries for any developing country. In our country, Iran, the automobile industry has made significant progress. But how is this progress achieved? To use a tool that can help work pressure but increase efficiency. In the automotive industry, rubber rollers are used to transfer materials on conveyor belts for automobile production, to transmit power in automobile manufacturing machinery, and to perform various operations in the automotive industry. For example, rubber rollers are used in conveyor belts for transporting car parts, in car assembly machinery, and in car paint machines.

Packaging Industry

Packaging is important for any business. In fact, packaging can be the showcase of a product and that brand. For this reason, the best tools should be used for proper packaging. One of these tools is a rubber roller. Do you remember when we said we use rollers to transfer materials? This is exactly what we are talking about. Rubber rollers are used to transport materials on packaging conveyors. For example, rubber rollers are used in conveyor belts for transporting packaged products, in product filling and packaging machines, and in product gluing machines. This can speed up and improve the packaging process.

The cost of buying and repairing rubber rollers

You may also be encouraged to buy this product. One of the questions that arise for related business owners is the price of this product. Here we must say that the cost of buying rubber rollers depends on various factors such as the size, material and quality of the roller. The cost of buying rubber rollers is higher than other rollers. But keep in mind that the lifespan, efficiency and range of activities that can be done with this roller is much more than others. But apart from the cost of buying this element, there is also the cost of repairing it. First of all, we must say that these rollers require less repair and the repair process is easier and faster. The cost of repairing rubber rollers also depends on various factors such as the extent of damage to the roller. In general, the cost of repairing rubber rollers is lower than other rollers.

When do you need to repair or replace the rubber roller?

Rubber rollers usually do not need to be repaired or replaced under normal conditions. However, if the rollers are subject to wear, corrosion or other damage, they may need to be repaired or replaced. Here are some signs that rubber rollers need repair or replacement:

- Cracks, tears or other damage to the tire surface

- Deformation or indentation in the tire surface

- Excessive tire wear

- Corrosion or damage to the shaft or bearing

If you notice any of these symptoms, you should have the rollers checked by a professional. An expert can determine if the rollers need to be repaired or replaced.

Repair and replacement process

Repairing rubber rollers usually involves replacing the damaged rubber surface. This can be done using a process called “coating”. In the coating process, a new layer of rubber is placed on the damaged surface of the roller. If the rollers are badly damaged, they may need to be replaced. Replacing the rollers is a relatively simple task that can be done by a professional. By repairing or replacing rubber rollers in time, you can prevent their damage and extend their life.

Safety tips when working with rubber rollers

Rubber rollers are important industrial equipment. It is necessary to observe safety tips when working with rubber rollers to avoid possible accidents and injuries. Some safety tips to follow:

Before starting work, make sure the rollers are in a safe condition. Look for any cracks, tears or other damage. Do not use rollers if they are not in safe condition.

Use proper safety equipment when working with rollers. This equipment should include safety shoes, glasses and gloves.

Avoid placing your hands or other body parts in the path of the rollers.

When working with large rollers, get help from a colleague.

If the rollers are exposed to corrosive substances, use rollers that are suitable.

If rollers are exposed to toxic substances, use appropriate safety equipment to protect yourself from exposure.

Thank you for your cooperation with us in this article. As you have seen and read, today and in this article we discussed and introduced the rubber roller. These industrial products act as one of the most important industrial tools. You should also know that because these rollers are working continuously for many hours, they should be taken care of a lot. Keep in mind that this procedure may only take a few minutes of your time on a daily basis. But the result is the correct operation of the roller for a long time without the need for repair or replacement. Mabanapaya Industrial Group operates as a specialized manufacturer of rubber rollers. Also, the repairs of the components of this roller, i.e. shaft and bearing, are also done in this complex. You can directly contact the experts of Mabanapaya to get more information and purchase advice.