rubber pieces

Rubber pieces are made from a combination of rubber and other materials. Rubber is an elastic material that is made from organic compounds and has properties such as flexibility, resistance to pressure and impact, resistance to moisture and chemicals.

Surely all of you in industrial or even non-industrial activities have come across parts that have a soft and flexible texture. We know these parts as rubber parts in different industries. They have many uses. Rubber pieces are among the products that have many applications in various industries. Due to their special features, these parts can withstand pressure, impact, vibration and different weather conditions. For this reason, rubber pieces are used in industries such as automotive, oil and gas, agriculture, construction, etc. The importance of these parts becomes clear when we see that there is a problem without them. But the introduction of these parts does not end there. Today, in this article, we are going to examine rubber parts. We also intend to know the importance of using them in different industries and check their manufacturing process.

rubber pieces

Defining rubber pieces may not be a very difficult task. Rubber pieces are made from a combination of rubber and other materials. Rubber is an elastic material made from organic compounds. This material has properties such as flexibility, resistance to pressure and impact, resistance to moisture and chemicals. Note that these parts can be manufactured and supplied in a wide variety of elements. Elements whose use can even contribute to the better performance of other industrial elements. We said that rubber parts are produced in different types. Some types of rubber parts are:

Rubber band

A rubber band is a piece made of rubber and has a rectangular or round cross-section. Rubber tape is produced in different types, including sealing rubber tape, insulation rubber tape, impact rubber tape, etc. Rubber sealing tape is used for sealing and insulating connections. This tape is used in various industries such as automotive, construction, oil and gas, etc. But insulating rubber tape is used to insulate against heat, humidity and chemicals. Insulation rubber tape is used in various industries such as food industry, pharmaceutical industry, chemical industry, etc. These tapes are mostly made of VITON tires.

Rubber bumper

A rubber bumper is a part made of rubber and used to reduce shocks and vibrations. This rubber piece is produced in different types, including simple, screw and spring rubber bumpers. A simple rubber bumper is a piece that is connected to the desired place in a simple way without screws. It is used in various industries such as automobile manufacturing, building construction, industrial equipment, etc. But the screw rubber bumper is connected to the desired location using bolts and nuts. It is used in various industries such as automobile manufacturing, building construction, industrial equipment, etc. Also, the spring rubber bumper is a part that has a spring and can reduce shocks and vibrations well. This type of shock absorber is used in similar industries as before.

Rubber cushion

Maybe the name of this product seems a little strange to you. A rubber cushion is a piece made of rubber and used to absorb shocks and vibrations. It can be said that the use of cushions is the same as rubber bumpers. Rubber cushions are produced in different types, including simple rubber cushions, screw rubber cushions, spring rubber cushions, etc. Its simple type is a piece that is connected to the desired place in a simple way without screws. The screw rubber cushion is attached to the desired location using screws and nuts. But the spring rubber cushion that has a spring can absorb shocks and vibrations well. All three of these items are used in various industries such as automobile manufacturing, construction, industrial equipment, etc.

Spiral hydrotest corner

Spiral hydrotest corner is a piece made of rubber and used to prevent water leakage in hydrotest tests. The corner of the spiral hydrotest has a shape similar to the letter U, and there are flanges at both ends that are connected to the pipes by means of bolts and nuts. Now, you may ask, what does the hydrotest test include? It is a type of pressure test that deals with leakage test, durability or volume expansion measurement. This test determines if the device is leaking or not. It also determines the durability of the device or device against pressure. It is very important to perform this test when making fire extinguishers or oxygen canisters.

Siebel Hydrotest RB

Siebel Hydrotest RB is a piece made of rubber and used to prevent water leakage in hydrotest tests. This sibil has a circular shape and there is a hole in the middle that is connected to the pipe by a screw. With this short description, you can understand the great importance of this piece. It can be used in various industries such as pharmaceutical, petrochemical, etc. These are enough to understand the importance of this element.

The importance of using rubber parts in industry

So far in the article, you may have realized the importance and many uses of rubber pieces. But the four main features of these parts have caused them to be used a lot.

- Resistance and strength

- flexibility

- Resistance to moisture and chemicals

- Insulation against sound and heat

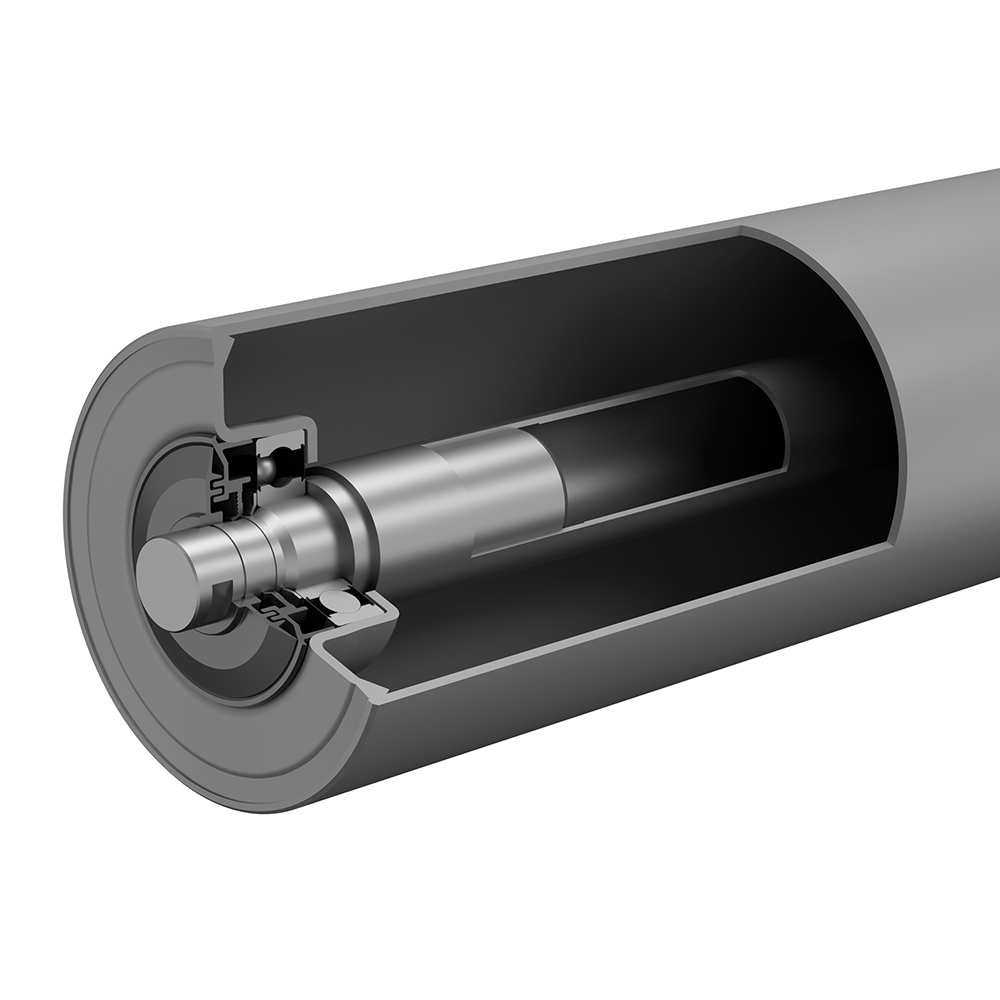

Let’s mention a few examples to show how useful these features are. First imagine an industrial roller. How the roller works correctly is very important in various industries. The use of rubber pieces reduces the impact on the roller. Or, for example, imagine an industrial hood with a strange shape. A flexible rubber should protect it. Tires are flexible because they are made of elastic material. Also, because of their texture, they can be resistant to sound, heat and humidity.

Production process of rubber parts

These parts can be produced in different ways and ready to use. Here we will introduce the three main methods of producing rubber pieces. Before introducing the methods, it is not bad to tell you something. Note that each method has its own characteristics. Therefore, a special method should be used to make different parts. Otherwise, a good result will not be obtained.

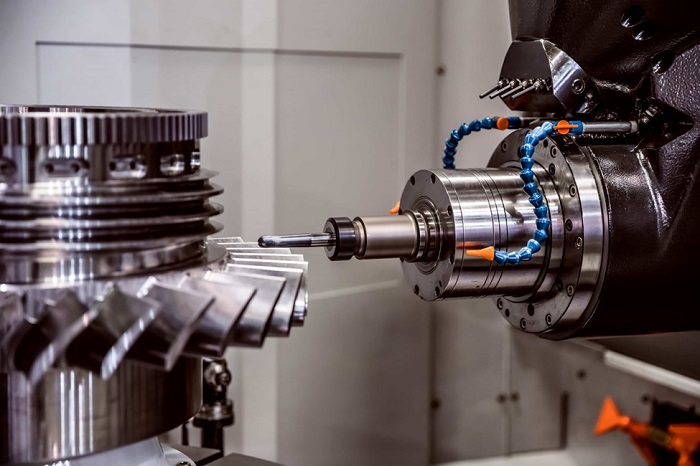

Injection molding

This method can be considered the simplest and most common method for producing rubber pieces. The use of this method started many years ago and is still one of the main and important ways. Now let’s examine the process of producing rubber parts with this method. In this method, the melted rubber compound is injected into the mold. After cooling, the rubber piece is produced and ready for consumer use.

Compression molding

But let’s go to another common method of producing a rubber piece. Before introducing this method, it is necessary to mention one point. Note that the pressure molding method is used to produce hard and strong rubber parts. The way to do it is that the rubber compound is pressed into the mold and after cooling, the rubber part is produced. The final product can be used in places where the part is under a lot of pressure.

Extrusion

Extrusion is another main method of producing a rubber part. In fact, this method can be considered indirect condensation. How to do it? In this method, the rubber compound is continuously removed from the mold. Then the product will be ready to use after cooling. This method makes the final product have high strength. Why? Because due to high pressure, materials pass through a small cross section and their power increases significantly. This method is a newer method than injection and pressure methods.

Rubber pieces in various industries

So far in the article, we have mentioned several times that rubber pieces can be used in various industries. These industries can even be vital industries in the growth and development of a country and its people. In the following, we will examine some of these industries.

automobile manufacturing

Automobile manufacturing is one of the most important industries in developed countries. In the automotive industry, rubber parts are used for various applications such as sealing, insulation, seismic, etc. Some of the rubber parts used in cars are: tires, door rubber, washers and O-rings.

Oil and Gas

In countries that have many natural resources, it is very important to pay attention to the correct process of the operation of these industries. There is a lot of sensitivity in the oil industry. One of the ways to increase control over different devices is to use plastic parts. Among these parts, we can mention diaphragm, bumper and cushion. These parts can be useful in impact and insulation.

agriculture

In our country, i.e. Iran, the agricultural industry is very popular, just like the automobile industry and oil industry. In agricultural industries, rubber parts are used for various applications such as irrigation, transportation, earthquakes, etc. Some of the rubber parts used in the agricultural industry are: irrigation hoses, conveyors and shock absorbers. Using these elements can help farmers a lot.

construction

Every day, with the increase in population, not only in Iran but in the whole world, it is necessary to use different parts for a better life of people. In the construction industry, rubber parts are used for various applications such as sealing, insulation, impact, etc. Some of the rubber parts used in the construction industry are: washers, O-rings, conveyor belts and shock absorbers. It is interesting to know that some people also use rubber parts to make windows.

medical

We all know the importance of medical science. In fact, medical science is a science on which human lives depend. The daily progress of the world in the medical industry has caused that the manufactured and advanced devices need quality and useful parts. Rubber parts can also be used in this industry. For example, in making oxygen capsules, rubber parts can be used for insulation.

Other industries

Rubber parts are also used in various other industries such as pharmaceuticals, aerospace, food industries, etc. Using quality parts makes people have less need to repair the devices they have. For this reason, it is very important to pay attention to the quality of rubber parts that are used in various objects. Mabanapaya Group, specialized in the production of various rubber parts, is ready to help you.

Thank you for joining us in this article. As we learned in this article, rubber parts are among the products that have many applications in various industries. Due to their special features, these parts can withstand pressure, impact, vibration and different weather conditions. For this reason, rubber parts are used in industries such as automotive, oil and gas, agriculture, construction, etc. Currently, the production of rubber parts is done using different methods. Choosing the right method for producing rubber parts depends on various factors such as the type of part, the dimensions of the part and the amount of production. Considering the advantages of using rubber parts, it is expected that the use of these parts in various industries will increase in the future. Mabanapaya Industrial Group, specializing in the production of high-quality rubber parts, is ready to receive your orders. You can contact the collection experts for more information.