If you have a little knowledge about different industries, you know the importance of metal parts. Metals are among the most widely used materials in various industries. These materials are used in many applications due to their high resistance and strength. However, metals also have disadvantages, including being susceptible to wear and corrosion. Now you have to think of measures to prevent these parts from being destroyed. Now you may ask what is the solution? One of the most common solutions used for this issue is the use of rubber coating. Using rubber coating on metal parts can help to solve these disadvantages. Today, in this article, we are going to examine the rubber coating of metal parts. If you are also interested in this topic, follow us to the end.

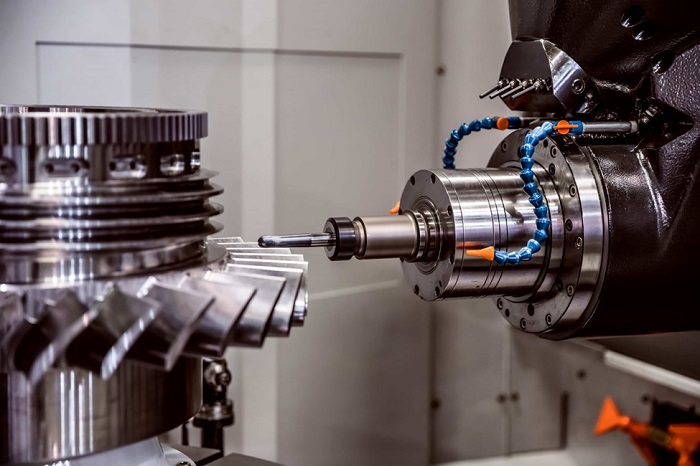

The use of metal parts in various industries

Metals are among the most widely used materials in various industries. These materials are used in many applications due to their high resistance and strength. Among the uses of metals in industries, the following can be mentioned:

- construction

- automobile manufacturing

- Food industry

- petrochemical

- Oil and gas industries

Metals are used in these industries as raw materials or parts and equipment. For example, in construction, metals are used to make building frames, bridges, and other structures. In automotive industry, metals are used to make car body, engine, and other car parts. In the food industry, metals are used to make kitchen equipment, packaging machines, and other equipment needed by these industries.

Advantages of using quality rubber coatings on metal parts

Using quality rubber coating on metal parts can bring the following benefits:

We said that the use of rubber coating on metal parts can prevent metal from coming into contact with natural and artificial destructive substances. For a better understanding, imagine an iron nail. The contact of the metal surface with water and oxygen easily oxidizes the nail. Using a rubber cover prevents this from happening.

Certainly, one of the things that all businesses pay special attention to is the cost of equipment maintenance. If you own an industrial unit, you know that paying attention to cost savings can bring more profit. In addition, this case causes that the speed of doing things does not slow down and high work efficiency is maintained.

Due to their inflexibility, metal parts require that the conditions for their work be fully prepared. So it should be noted that creating normal conditions for these parts is very important. Using plastic coating on metal parts can be effective in the correct functioning of these parts.

But in addition to all the things we said, the use of rubber covers can bring safety for employees. Let’s take an example to better understand the issue. You know that all metals are conductive. Now this conduction can be both heat and electricity. The rubber coating helps prevent these from being transferred to the people handling the parts.

Disadvantages of using poor quality rubber coating on metal parts

You saw that in the previous part, we examined the advantages of using high-quality plastic coating on metal parts. Now, in this section, we are going to investigate the disadvantages of using low-quality rubber coating on metals. This section does not need much explanation. In fact, it is better to say that in such a situation, the opposite of what we said before occurs. what does it mean? That is, we will see a decrease in the lifespan of metal parts, an increase in maintenance costs, a decrease in the proper functioning of metal parts, and a decrease in safety. The occurrence of these cases easily causes the activity of a group to be disrupted. So keep in mind that the cost of using quality coatings may be higher, but the performance they offer you is also higher.

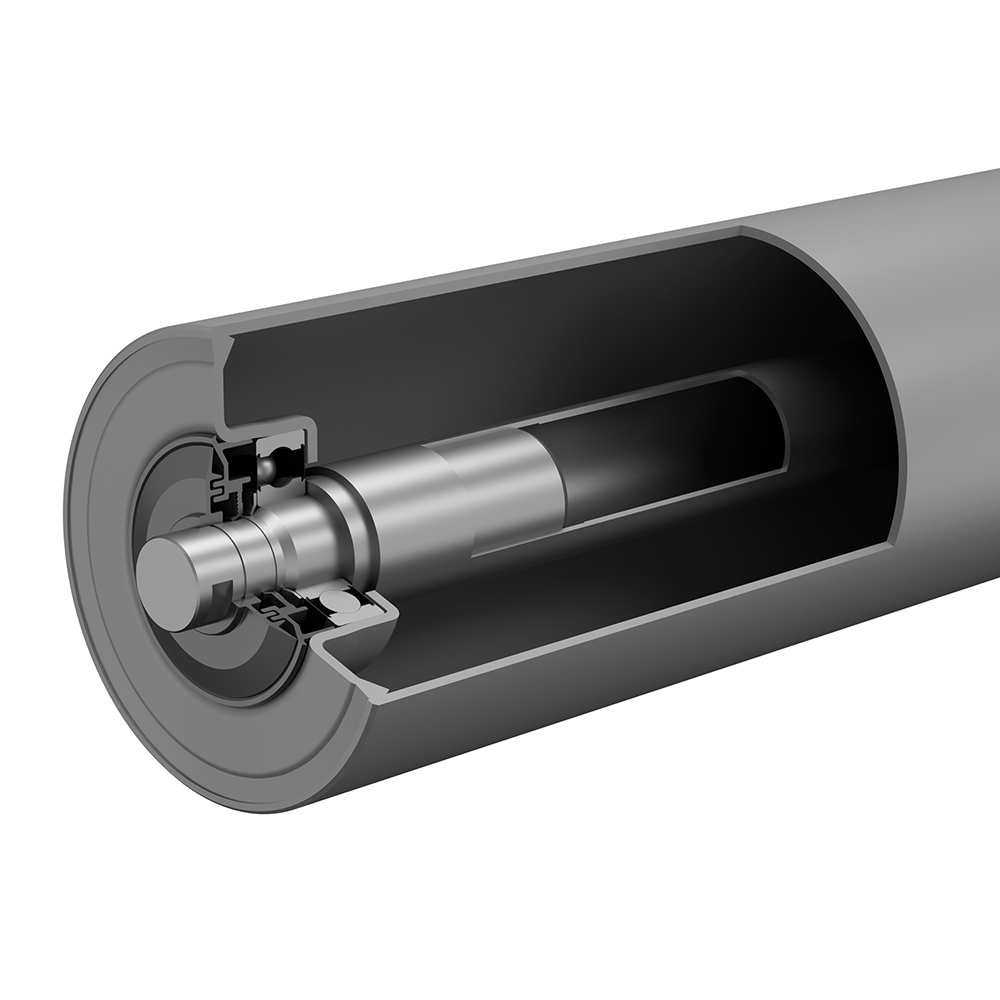

Using a rubber coating on the roller

Rollers can be defined as hollow cylinders that are used for various purposes. They can be used to transfer materials, transfer power, smooth and polish different parts and surfaces, create handmade elements, etc. Rollers consist of three main parts. The body of the roller, which is its main part. Paying attention to the strength of this part can increase the efficiency of the roller. The next part is the roller shaft. In fact, the roller shaft can be considered the main factor of continuous activity of the roller. The third part is the roller bearing. Bearings help the correct operation of the shaft and the main body together. Rubber coating is used on different types of rollers. Among the applications of rubber coating on rollers, the following can be mentioned:

- Material transfer rollers

- Printing rollers

- Press rollers

- Smoothing rollers

The cost of using rubber coating

One of the most important things that can always occupy the minds of related business owners is the cost of the materials they use. The cost of applying rubber coating on metal parts depends on several factors, including the type of rubber used, the dimensions and size of the metal part, and the method of manufacturing the rubber coating. In general, the cost of using rubber coating is relatively economical and can reduce the maintenance costs of metal parts. You saw that in the previous sections, we also examined the many advantages of these coatings. So keep in mind that using these elements can add many good features to your devices.

Thank you for joining us in this article. We are proud that you accompanied us until the end. You saw that in this article we discussed and introduced rubber parts on metal parts. We said that using rubber coating on metal parts can bring many advantages. These coatings can prevent wear and corrosion of metal parts and increase their lifespan. Also, they can improve the performance and safety of metal parts. We also said that using these elements at a reasonable price is very affordable. With the ISO 9001 certificate and guaranteeing the quality of production materials, Mabanapaya Industrial Group is ready to provide all kinds of rubber coating to you dear ones. You can contact us for more information and contact with relevant experts.