All of you are definitely familiar with rollers in different industries. In every industry we look at, we can see the undeniable impact of rollers. Of course, many people may not pay much attention to these industrial elements. But you should know that they are very important. But you may ask, how do these useful elements work? What is the secret of their continuous activity in consecutive hours? The roller shaft, as the backbone of these elements, provides their driving force. These elements play one of the most important roles in the activity of rollers. In fact, the roller shaft can be considered as a constant friend of the rollers. so that wherever there is a trace of the roller, we also see the presence of the shaft. Today, in this article, we are going to introduce and review the types of roller shafts. Stay with us.

What is a roller?

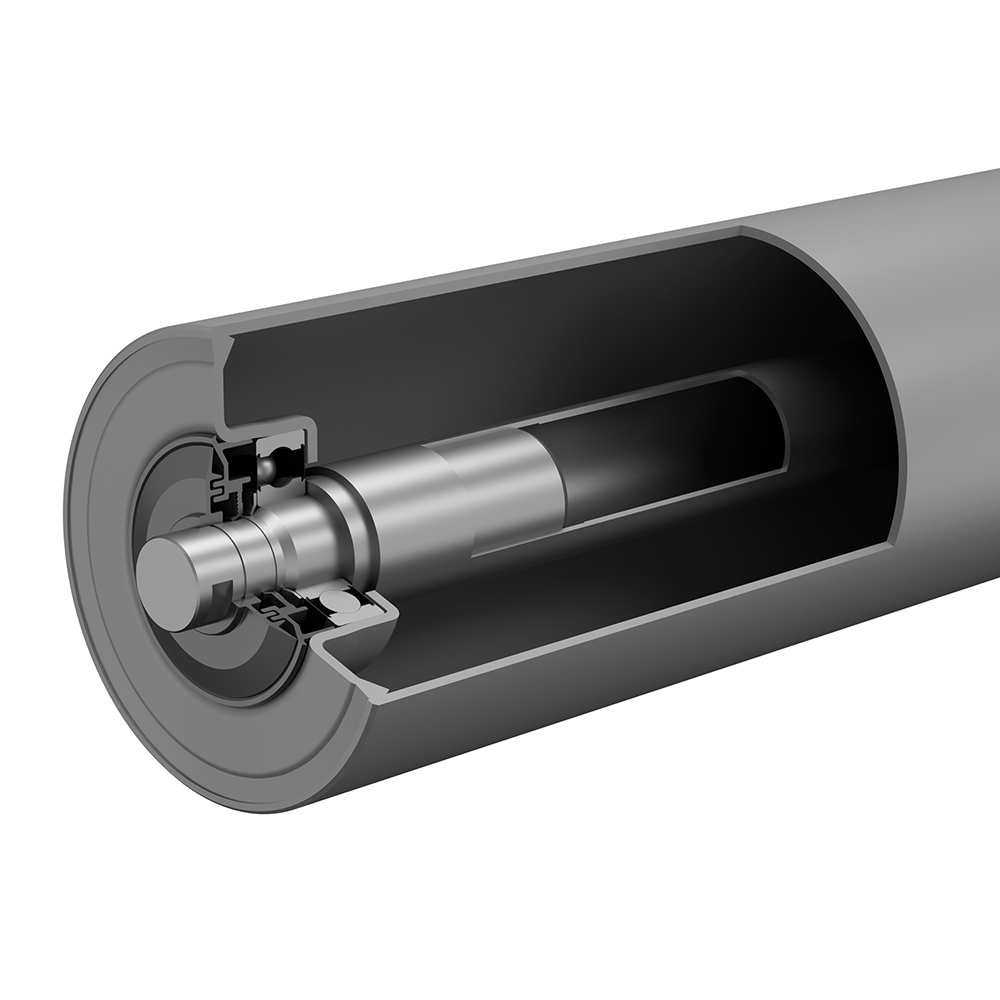

Let’s introduce the rollers first. Let’s check and see what is this cylinder that is made of power? Rollers are metal or plastic cylinders that move materials and products by rotating. From mass production lines to giant conveyor belts, rollers are an active presence wherever there is a need to move loads. Rollers are cylindrical shaped parts that are used to transfer force or material. They can be made of different materials such as metal, plastic or wood. Great care must be taken in making these parts because the smallest error in its operation can cause many losses. Generally, rollers are made of three main parts. Roller body, roller shaft and bearing. These three elements together can form a useful system.

What is a roller shaft?

Now let’s examine the beating heart of the rollers. We said that the roller shaft is the constant friend of the rollers. The roller shaft is a metal rod that is placed in the center of the roller and guides its rotation. The material of the shaft is made of steel or cast iron and it must be strong enough to withstand high load and torque. Generally, these shafts are connected to the body of the roller by means of an object called a bearing and help its operation. By now, you must have realized that shafts are very important. At the same time, you should know that the failure of these elements can bring disastrous results in industrial activity. One of the main activities of Mabnapaya Industrial Group is changing the roller shaft. In the following, we will briefly review the steps of changing the roller shaft.

Types of roller shaft

But now let’s get to the point. In this section, we are going to introduce the types of roller shafts. Before examining this issue, note that each type of roller shaft is suitable for a specific activity. For this reason, it is necessary to consult an expert in this field before choosing and using it.

Simple shafts

Let’s talk about the first and most used model of roller shafts. They are the simplest type of shafts that are suitable for rollers with low load and low speed. You must have seen this model of rollers many times, especially in many large and chain stores.

Hollow shafts

Have you ever noticed the very large and industrial rollers? You can see that they have a very high weight and are used for heavy activities. Hollow shafts are used for rollers with a large diameter and heavy weight.

Step shafts

But sometimes it is possible that a series of rollers need to quickly reduce their speed and torque in specific or random intervals. Step shafts should be used in this type of roller system.

Barbed shafts

But let’s start with the fourth type of roller shaft. There are some rollers that need to apply more friction force to the object during their operation. Also, this friction force is applied to themselves. In this type of rollers, spiked shafts should be used.

Advantages of using a quality roller shaft

Using a quality shaft can increase the life of the roller. Now you may ask why? A quality shaft reduces friction and wear and thus increases the life of the roller.

If you have experience working with rollers, you may have seen that sometimes due to the use of a poor-quality shaft, the roller has a bump and produces additional sounds. Using a quality shaft eliminates these issues.

We said that a quality shaft can reduce friction in a very visible way. This friction reduction can increase the efficiency of the roller in addition to increasing its life.

One of the things that industrial units are always looking for is to reduce many costs for more profit. Using a quality shaft reduces the need for repairs and maintenance, thus minimizing costs.

Symptoms of roller shaft failure

Despite the high quality, the roller shaft may also fail over time. But this failure may have signs that we can notice the failure of the roller when they occur. The first is the unusual sound. Making unusual noises by the roller can be a sign of its failure. Overheating of the roller is another sign of shaft failure. Overheating of the roller is a sign of excessive shaft friction and wear. Another sign of roller shaft failure is the reduction of roller efficiency. If you notice a decrease in the efficiency of the roller, you should consider repairing or replacing the shaft.

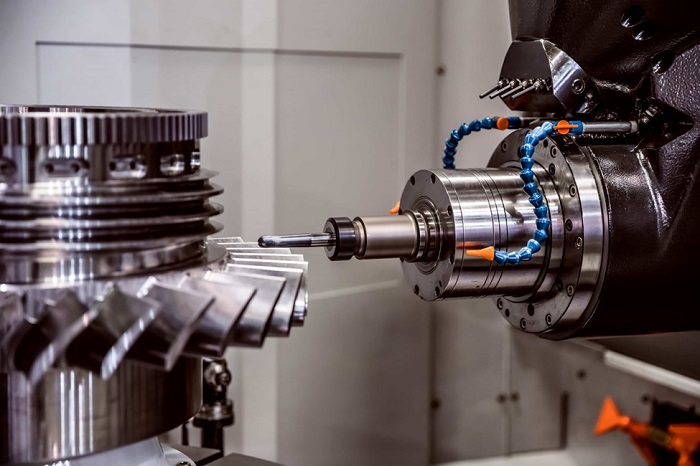

Procedures for replacing the roller shaft

Replacing the shaft is a relatively simple process that can be done using the right tools and following safety precautions. In this section, step by step, we will check the shaft replacement process.

1- Remove the roller from the device

Before doing anything, turn off the device and disconnect it from the power supply. Then, loosen the screws and nuts that connect the roller to the machine. In the next step, carefully remove the roller from the device.

2- Remove the bearings from the shaft

There are bearings on both sides of the shaft. You can use a bearing puller to remove the bearings. Place the bearing puller behind the bearing and remove the bearing from the shaft by twisting the nut.

3- Remove the shaft from the roller

You know that the shaft passes through the roller. You can use a hammer to remove the shaft. Tap the end of the shaft gently with the hammer to release the shaft from the roller.

4- Put the new shaft in the roller

Clean the inside of the roller before inserting the new shaft. This will remove impurities and excess shavings. Then, put the new shaft in the roller. Using a hammer, gently tap the end of the shaft to snap the shaft into place.

5- Put the bearings in the shaft

Place the bearings on both sides of the shaft. You can use a bearing press to fit the bearings. Place the bearing press against the bearing and push the handle into place.

6- Connect the roller to the device

Put the roller in place. Close the bearing, screws and nuts that connect the roller to the machine. Plug in the device and turn it on.

Safety tips when replacing the roller shaft

Maybe replacing the shafts is a simple process. But every industrial activity is required to observe a series of safety points. When replacing the shaft and before starting work, make sure that the machine is turned off and there is no electricity. Be sure to use gloves and safety glasses. Use appropriate and healthy tools. Also, if you don’t have experience, get help from an expert.

Thank you for joining us in this article. In this article, we examined the types of roller shafts, the benefits of using a quality shaft, signs of shaft failure and how to replace it. We hope this article was useful for you. We knew that by replacing the shaft, the endless dance of the rollers will start again. The gears of the industry will start moving and once again we will witness the production and creation of products. Mabnapaya Industrial Group specializes in the repair and production of rollers and its accessories. In this collection, we are proud to have the ISO 9001 technical certificate to cooperate with industrial units in this field. You can contact the experts and specialists of the collection to know about cooperation with Mabnapaya collection. Thank you for your cooperation.