Replacing the roller shaft

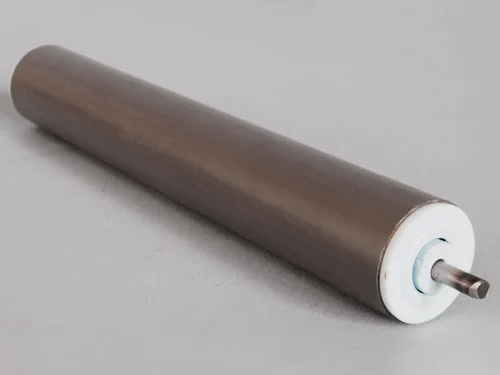

The roller shaft is an axis on which the roller rotates. Shafts are usually made of steel or other alloys and can be attached to rollers in a variety of ways.

With the advancement of technology, we have seen many effects in the industry. We also saw what new tools were created to help humans. Some of these elements may have expired, but many others are still serving humans. One of these devices, which has been available to humans since hundreds of years ago, is the roller. Rollers are one of the important components of many machines and industrial equipment. They are used to transmit power, move materials, and other applications. The shafts are the axes on which the rollers rotate. They are usually made of steel or other alloys and can be attached to the rollers in different ways. But sometimes these shafts may have problems. Today we are going to replace the roller shaft. Stay with us.

What is a roller?

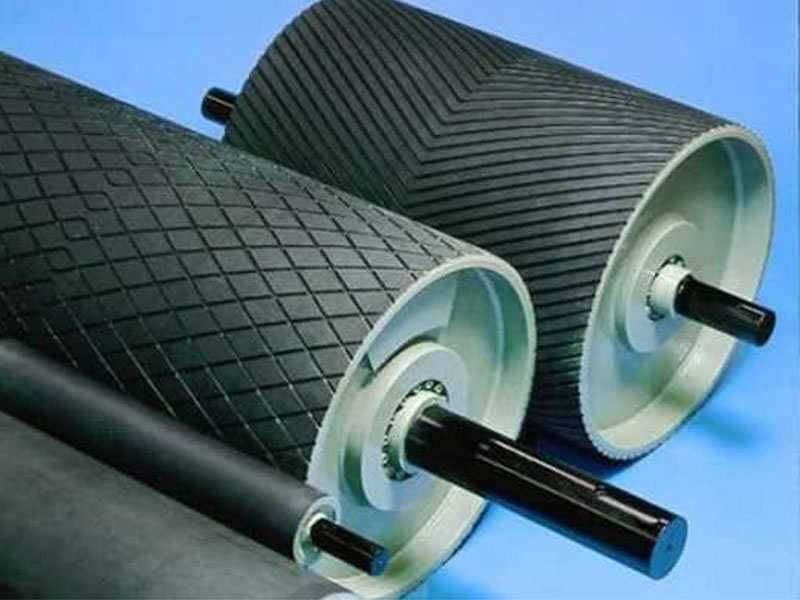

A roller is a round and flat object that is usually made of metal, plastic or rubber. Rollers are used for various purposes, including power transmission, moving materials, smoothing surfaces and producing products. Rollers can be used individually or in large groups. Single rollers are usually used for specific purposes such as transmitting power or moving materials. Group rollers are usually used for smoothing surfaces or manufacturing products. Rollers can be connected to other devices in different ways. They can be directly attached to the machine, or they can be attached via a shaft. One of the important uses of rollers in the industry is called polishing rollers. This method is used to smooth and polish metal surfaces.

Types of rollers

Steel rollers

Steel rollers are usually the strongest and most durable type of roller. They are used for heavy duty applications such as power transmission or moving heavy materials. You have definitely seen this type of roller. One of the common misuses of this is in the field of road and street construction. You have seen a car with a big roller on the front moving on wet asphalt and smoothing it.

Plastic rollers

Plastic rollers are usually lighter and cheaper than steel rollers. They are used for light applications such as smoothing surfaces or manufacturing products. Usually these rollers are not used heavily. Why? Because they may not have the ability and resistance. Of course, this does not mean that their gender is weak. These rollers are made of compressed plastic.

Rubber rollers

Rubber rollers are usually the most flexible type of roller. They are used for applications such as smoothing rough surfaces or manufacturing products. What is meant by producing products? Products that are close to the roller type. such as belts, etc.

Industrial rollers

Industrial rollers are commonly used for industrial applications such as product manufacturing or construction. They are usually made of durable materials such as steel or compressed and reinforced plastic. Industrial rollers are also used in industries such as road construction, which we mentioned a while ago.

Agricultural rollers

Agricultural rollers are commonly used for agricultural applications such as crop production or harvesting. They are usually made of durable materials such as steel or plastic. These rollers are used to level the land for the next crops. Also, sometimes they are used to pound agricultural products.

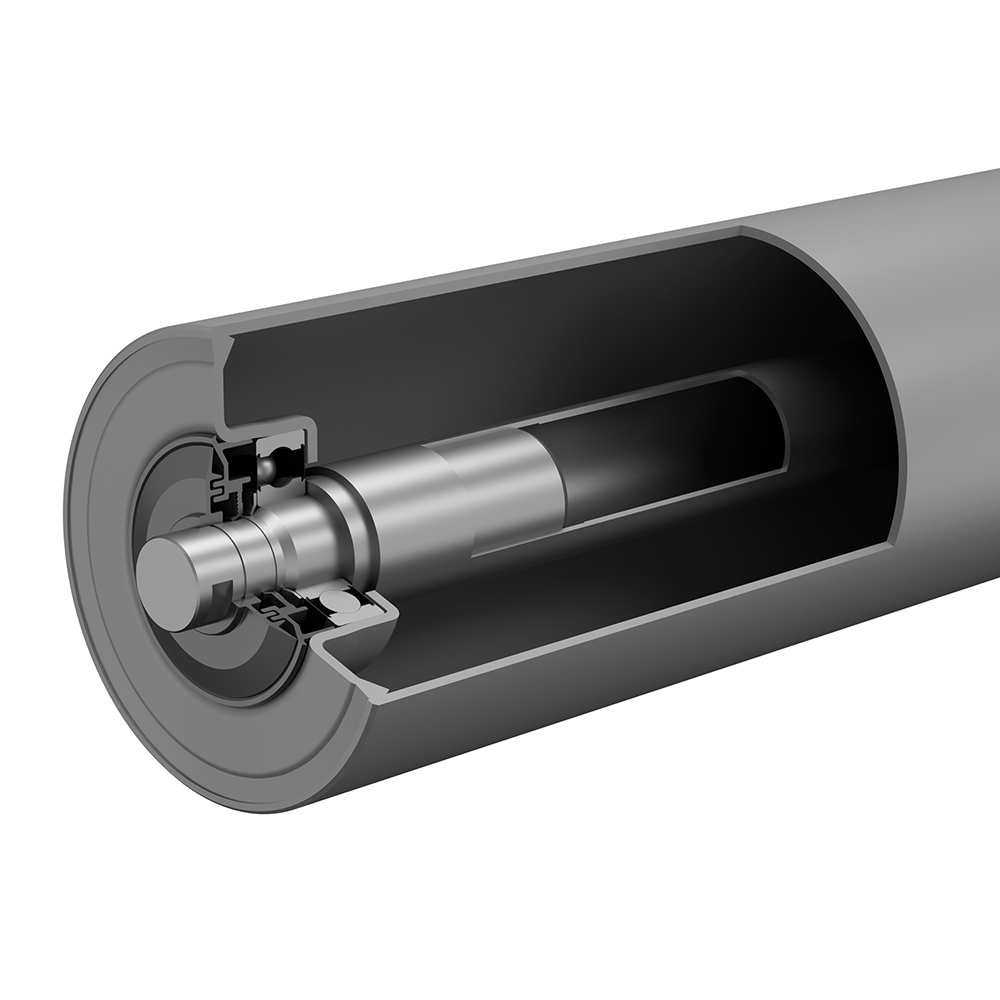

What is a shaft?

The roller shaft is an axis on which the roller rotates. Shafts are usually made of steel or other alloys and can be attached to rollers in a variety of ways. Roller shafts are commonly used in industrial machines. They are used to transmit force, move materials or smooth surfaces. In fact, it should be said that the main factor for the activity of rollers are these shafts. In a simpler definition, they can be considered as the constant companion of rollers. Without the shaft, the roller cannot perform its activity properly and a lot of damage is done to other objects such as the engine.

Advantages of roller shafts

We said that the roller shaft is a mechanical part that is used to transfer power and movement from one place to another. This piece consists of a metal shaft on which one or more rollers are mounted. The roller shaft has several advantages, including the following:

The roller shaft can transfer power and movement from one place to another with high precision. This is due to the use of smooth and polished rollers that prevent unwanted friction. Finally, in addition to high accuracy, it also increases the speed of operation.

The roller shaft is made of resistant materials such as steel or aluminum. This makes the roller shaft resistant to wear and corrosion and has a long life. Now you may ask why? Because the activity of the shaft and the roller together and in the direction of helping each other causes the pressure to be divided between them and consecutive failures are prevented.

The roller shaft can be adjusted according to different needs. For example, the distance between the rollers can be adjusted or the rollers can be coated with different materials. This makes it possible to increase the area of activity and use of rollers.

The roller shaft has a more reasonable cost than other methods of power and movement transmission. The reason is that this method is a more stable and long-lasting method. For this reason, you need to change and replace in many time intervals. That is why we say that it is economical.

Types of roller shafts

Straight shafts

Straight shafts are the simplest type of shaft. They have a smooth surface on which the roller rotates. Currently, this type of shaft can be considered as the most widely used type of shaft.

Grooved shafts

Splined shafts have grooves on their surface. These grooves can be used to connect the roller to the shaft.

Geared shafts

Gear shafts have teeth on their surface. These teeth can be used to transfer power from one device to another. Here we have seen some progress in the production and use of shafts.

Conical shafts

Conical shafts have a diameter that decreases from one end to the other. This type of shaft is usually used to connect different components with different diameters. We often see the use of this type of shaft in industrial machines with huge sizes.

Why should we replace the roller shaft?

A worn shaft may impair roller performance due to wear, corrosion, or breakage. Dysfunction of the roller can make the final products unable to show the required quality. Especially since the rollers are used in the roller polishing process, daily inspection of the roller shaft is very important. Replacing the worn shaft with a new one will make the roller work properly and increase its life. Replacement includes operations such as removing the worn shaft from the roller, preparing the new shaft for installation, and attaching the new shaft to the roller. In Mabanapaya Industrial Group, this service is provided by using the most advanced equipment and the most experienced specialists.

Procedures for replacing the roller shaft

Rollers and shafts are two essential components of many industrial machines and equipment. Rollers are used to transmit power, move materials and other applications. The shafts are the axes on which the rollers rotate. Sometimes the roller shaft may need to be replaced. This can happen for a number of reasons. Reasons such as shaft failure due to wear, corrosion or mechanical damage, the need to change the size or length of the shaft and the need to change the type or material of the shaft. Replacing the roller shaft is a complex process that should be performed by a professional technician. Note that doing this without prior expertise can cause expensive damage. such as personal injury and heavy financial damage. In this section, we provide a comprehensive and practical guide for changing the roller shaft.

Checking the roller shaft

Before replacing the roller shaft, it is necessary to examine it completely. At first, we have to examine its appearance so that we can find wear or corrosion on its surface. Then we need to measure the length and diameter of the shaft. After that, we should check the type and material of the shaft. Note that if the shaft is damaged or worn, it must be replaced. Also, if you need to change the size or length of the shaft, you will need to get a new shaft.

Choose a new shaft

There are a few things to consider when choosing a new shaft. The length and diameter of the shaft, the type and material of the shaft, the material of the roller and the load and the rotation speed of the roller. The length and diameter of the shaft must match the length and diameter of the old shaft. The type and material of the shaft must also match the type and material of the roller. You also need to make sure that the shaft can handle the load and speed of the roller.

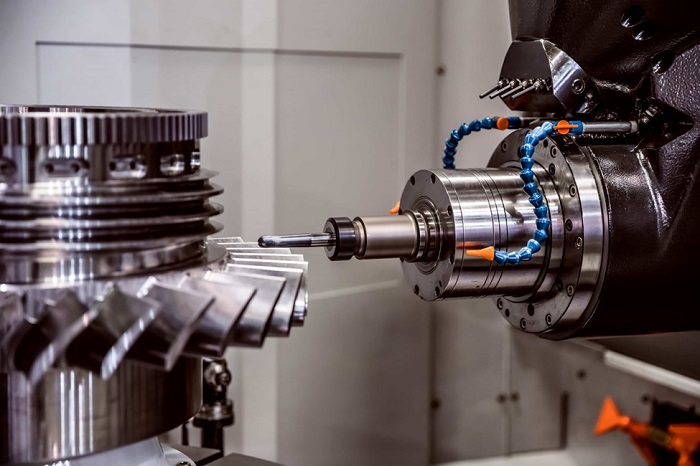

Preparation for shaft replacement

Before starting to replace the shaft, you must prepare the right equipment and tools. This includes items. Hand tools, such as wrenches, screwdrivers, pliers, and hammers, power tools, such as drills, hacksaws, and milling cutters, safety equipment, such as safety glasses, gloves, and masks. You should also prepare the necessary equipment and tools to remove the roller. This includes a jack or lift, clamps and disassembly tools.

Remove the roller

The first step in changing the shaft is to remove the roller. This is usually done using a jack or lift and clamps. After removing the roller, you can access the shaft. At this stage, it is very important to pay attention to safety issues. Keep in mind that if you want to lift an industrial roller or another heavy roller, be sure to use a jack and machine tools. Lifting the roller manually can cause serious physical injuries. So be sure to consider this point.

Removing the old roller shaft

The old shaft is usually removed using hand or power tools. If the shaft is welded, welding methods must be used to remove it. Otherwise, the shaft can be separated from the roller by just loosening a few screws. As in the previous step, if you use machine tools in this step, it will be easier for you. In addition, there is a higher safety in your work.

Installing a new shaft

Installing a new shaft is usually done using hand or power tools. If the roller shaft was previously welded, welding methods must be used to install it. Otherwise, you don’t have a hard time installing it. You can use it again with just a few screws.

Close the roller

After installing the new shaft, you need to reinstall the roller. This is usually done using a jack or lift and clamps. We said a while ago that moving the roller manually using human power is risky. For this reason, for greater safety, it is better to use a jack or lift and related machines for moving.

Roller test

This is usually done using a test load. Note that this test should be done in such a way that there is not much pressure on the shaft and roller at first. This will cause damage to the device very quickly and will make you have to think about replacing the roller shaft again. As recommended by experts, start with low pressure first. If the device was successful and did not withstand heavy pressure, gradually increase the pressure and then measure it.

safety tips

To perform the roller shaft replacement process, you need to pay attention to some safety points. First, make sure that the device is off and the power is off. If this is not the case, something irreparable will happen. In the second step, use safety equipment such as gloves, glasses and masks. Using these few simple tools will help you to continue your work more easily. In the next step, be sure to use suitable and standard tools for your work. By doing this, you can be sure that there will be no problems while working. In the last step, we must say that you must use the help of other people. This is important because you can concentrate and be more careful. What is the result of observing all these points? Getting your job done right without a problem.

The cost of replacing the roller shaft

One of the important questions that arise for industrial groups is how much is the cost of replacing the roller shaft? The cost of replacing the roller shaft depends on various factors, including the type and size of the roller shaft, the material of the roller shaft, the cost of materials and components, and the cost of the repairman’s wages. In general, the cost of replacing the roller shaft varies from several million tomans to tens of millions of tomans. If the roller shaft is badly damaged, it may be necessary to replace the entire roller. In this case, the cost of replacing the roller will increase significantly. To know the exact cost of replacing the roller shaft, it is better to consult a professional repairman. To reduce the cost, it is better to do several things. Using reliable and experienced repairmen, consulting with several other repairmen and using high-quality materials. In this way, costs are significantly reduced.

Thank you for your cooperation with us in this article. You saw that in this article we discussed and introduced the roller, shaft and the activity of the shaft and roller together. We also checked how the replacement of the roller shaft should be done and how much it would cost. We hope that the material presented in this article was useful to you. We at Mabanapaya Industrial Group, having professional experts in the field of implementation and replacement of roller shafts, are ready to provide you the necessary help in this field. For this, you just need to contact the experts and support team of Mabanapaya collection.