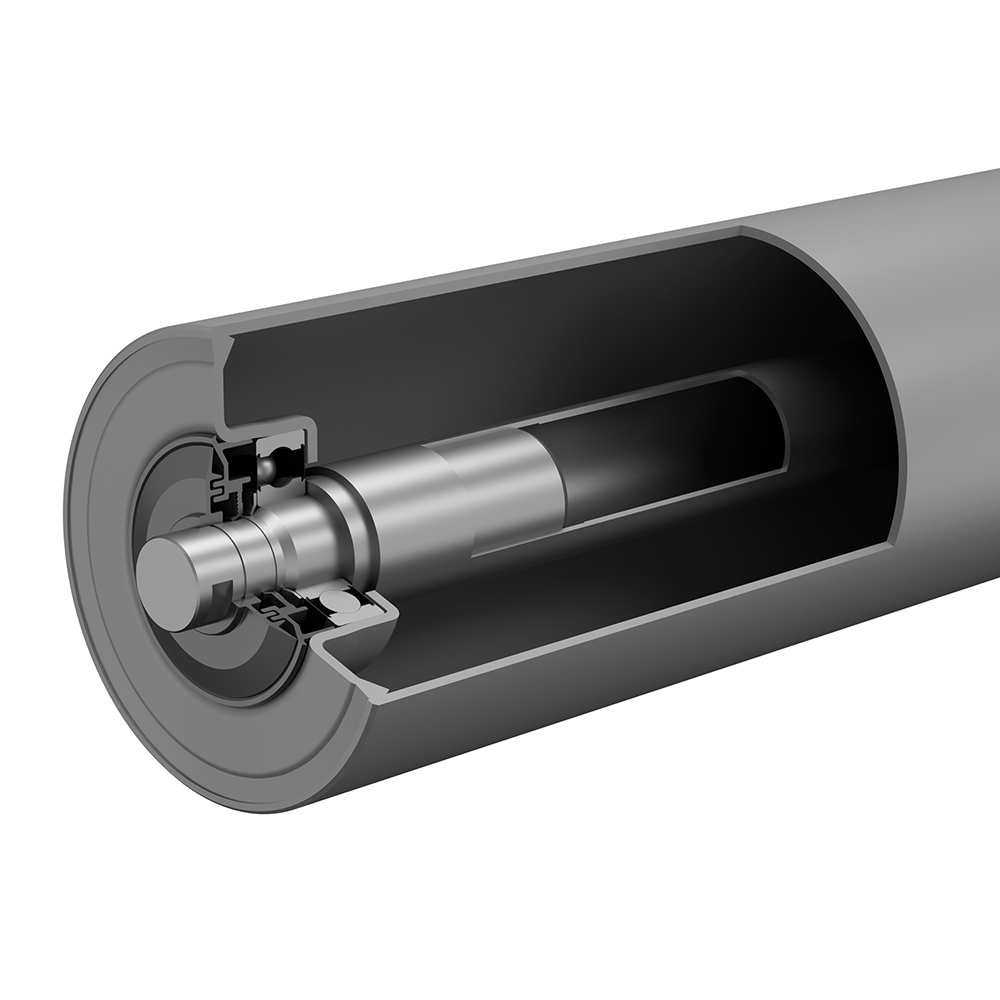

Repairing the roller bearing

Roller bearing is one of the important components in rollers. They are used to support the roller and reduce the friction between the roller and its axis.

Rollers are one of the important components in many machines and equipment. They are used to transmit power and move other machine components. Bearings are also one of the important components of rollers. They are used to support the roller and reduce the friction between the roller and its axis. Over time, the bearing seat on the rollers may become damaged. These damages can be caused by various factors such as wear and tear, corrosion, and impact. Damage to the bearing seat can reduce the performance of the roller and even cause its failure. In this article, we will examine the repair of the bearing on the roller. First, we introduce rollers and bearings. Then, we will check the different methods of repairing the bearing seat. Finally, we will state the important safety points that must be observed when repairing the bearing housing.

What is a roller?

The roller is one of the important components in many machines and equipment. They are used to transmit power and move other machine parts. Rollers come in different shapes and sizes. They can be made of various materials such as steel, cast iron, and aluminum. Also, in addition to these metals, the rollers can be made of compressed plastics or rubber. Rollers are used for various purposes including power transmission, moving materials, smoothing surfaces and manufacturing products. Rollers are divided into two general categories: axial rollers and radial rollers. Axial rollers are used to transmit force in an axial direction. Radial rollers are used to transmit force in a radial direction. But one of the important components in the work of the roller neck is the bearing. In the next part, we are going to introduce bearings.

What is a bearing?

Bearings are one of the important components in rollers. They are used to support the roller and reduce the friction between the roller and its axis. Bearings come in many shapes and sizes. They can be made of various materials such as steel, bronze, and durable plastic. Bearings are divided into two general categories: rolling bearings and roller bearings. Rolling bearings use rolling components such as balls or balls to reduce friction. Roller bearings use roller components such as cylinders or spheres to reduce friction.

Features of quality bearings

You may be wondering what features a quality bearing should have. It is very important to pay attention to this issue. Why? Because choosing the right bearing can help you a lot in your business. The best roller bearing should have the following features:

The first and most important characteristic that a quality bearing should have is high load tolerance. Rollers are often subjected to heavy loads. Therefore, the bearing used must be able to withstand these loads safely. For this reason, you should pay attention to the fact that the bearing you choose must have a high load tolerance.

Rollers are often used in harsh environments. You also know that the rollers are working for many hours and are used a lot. These few short points are enough to know how important it is to take care of them. Therefore, the bearing used must be able to withstand these conditions and have high durability.

Bearings should work with minimum friction and energy loss. This reduces energy consumption and increases the efficiency of the device. You might say to yourself in the first place that in industry, high energy consumption by parts is normal. But it is not like this. This high consumption can cause damage to devices. It can also cause your consumption costs to increase.

You know that all business and industry groups are trying their best to reduce costs. In fact, it is better to say that they are trying to prevent excessive expenses. Instead of these exorbitant costs, it can be the use of tools that have an affordable price. The cost of bearings is one of the important factors in their selection. The bearing used should be selected according to the budget and project requirements.

In addition to these features, the bearing used must be compatible with the type of application of the roller. For example, if the roller is exposed to water or chemicals, waterproof or rustproof bearings should be used.

In this section, we examine some types of bearings that are suitable for rollers.

Round bottom bearing

This type of bearing has cylindrical rollers with a round base that can withstand heavy axial loads. As a result, it is suitable for use in rollers that perform heavy activities.

Needle bearing

This model of bearing has very thin cylindrical rollers. Like the previous model, these bearings can withstand very heavy axial loads. As a result, this model can also be used in heavy industrial rollers.

Spherical bearing

This type of bearing has spherical rollers that can withstand both radial and axial loads. Note that using this type of bearing is not suitable for heavy work and can cause other serious injuries.

Bearing repair methods

Sometimes, the bearings may be damaged due to excessive use of the roller device. In this situation, we have to repair or replace them. The issue of repairing and replacing bearings is completely separate. It is necessary to know that when replacing bearings, their place on the body of the roller may be damaged. There are different ways to repair the bearing seat. Choosing the right method depends on various factors such as the type and severity of the damage, the size and shape of the roller, and the type of bearing. In the following, we will examine some of these methods. So stay with us.

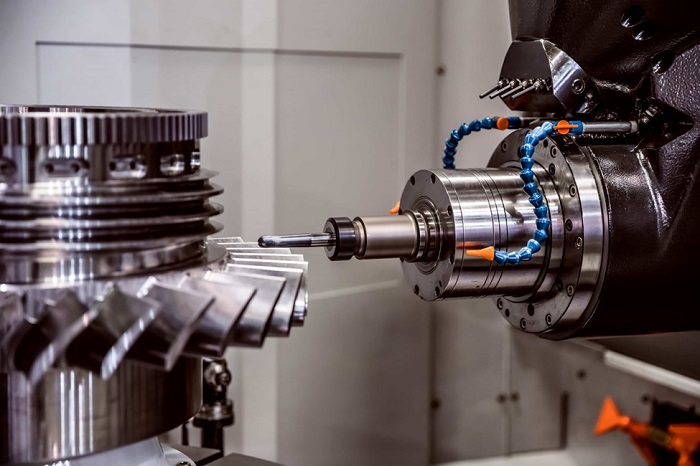

Grinding method

Grinding is one of the common ways to repair the bearing. In this method, the place of the bearing is removed using grinding to get the right size and shape. In this method, we roll it on the surface using a device with special sandpaper on it, in a rotational or radial manner. Note that this should only be done on the surface of the bearing seat.

Welding method

Welding is one of the methods of repairing the bearing seat, which is used in severe cases. In this method, the bearing seat is repaired using welding. Note that using this method for small injuries is not appropriate and economical at all. As we said, we use the welding method when there are big and serious damages. In this way, the work proceeds in a simpler and more correct way and we reach the desired result.

The effect of repairing the bearing seat in the work process

Bearing seat repair can have a big impact on the work process. If the bearing is not repaired properly, it can reduce the performance of the roller and even damage it. You know that we use rollers for ease and speed in doing things. So we know that reducing the performance of the roller is not a good thing at all. In the following, we describe some of the effects of repairing the bearing seat in the work process:

Reduce friction

You are familiar with the word friction. Friction means the surface of two objects touching each other. Repairing the bearing seat can reduce the friction between the roller and its axis. What is the result of reducing roller friction? This makes the roller move easily and improves its performance. This is exactly what we want from a roller. High speed of work.

Increased life expectancy

Repairing the bearing seat can increase the life of the roller. Imagine a car that moves a lot of cargo every day. On the other hand, imagine a car that is turned on once every two days and travels a short distance. Definitely, the first car ends its life faster. The same is true for rollers. The correct operation of the bearing reduces the pressure on the roller and increases its life.

Reduce the cost of repairs

We said that using a healthy bearing reduces the pressure on the roller. Repairing the bearing seat can reduce the cost of repairs in the future. This is due to reduced damage to rollers and other parts. Of course, this does not only apply to bearings and rollers. In any other industrial tool, when the necessary procedures are done, we will see an increase in the life of the devices.

The result of not repairing the bearing seat

You saw that in the previous section, we told the result of repairing the bearing. Now it’s time to tell the result of not repairing the bearing. In fact, what we are going to say in this section is completely contrary to what we said in the previous section. That’s why we take a quick look at them. Failure to repair the bearing can increase friction. Increasing friction can decrease the speed of the roller and increase energy consumption. Also, increased friction can cause the roller and other parts to heat up. Also, this increase in friction can increase the pressure on the roller. This can reduce the life of the roller and other parts. What is the result? Roller failure. If the damage to the bearing is severe, it may cause the failure of the roller. The failure of the roller can cause the machine to stop working and cause damage.

When should the bearing be repaired?

With the current knowledge, you may not know when the device’s bearing has a problem and needs to be replaced. Repairing the bearing seat is an essential action that should be done as soon as possible. Failure to repair the bearing seat can cause serious problems and high costs. If you see any of these signs, it is best to have the roller checked by a professional repairman immediately. Here are some symptoms of bearing seat failure that can help you determine if a bearing seat needs repair.

unusual sound

Certainly, one of the factors that tell us that a device needs repair is the occurrence of unusual sounds. It doesn’t matter if it’s a car or a computer or a roller. One of the first signs of bearing failure is hearing an unusual noise from the roller. This sound can be vibrating, whistling, or clicking.

Heat increase

We said that the damage of the bearing and its place in the roller can increase the friction in the roller. What is the result of increased friction? increasing the pressure on the roller and consuming more energy and finally producing heat. An increase in the heat of the roller can also be one of the signs of bearing failure.

Roller vibration

In addition to the features we mentioned earlier, the bearing can help the device stay in place. When you notice that your device seems to have excessive and abnormal vibrations, you should think about repairing it. Therefore, the vibration of the roller can also be one of the symptoms of the failure of the bearing.

The cost of repairing the bearing

The cost of repairing the bearing seat depends on various factors such as the severity of the damage, the size of the roller, the type of bearing, the cost of materials and the repairman’s salary. In general, the cost of repairing the bearing seat with the grinding method is lower than the cost of the repair with the welding method. The payment fee is also usually calculated separately. For example, the cost of repairing the bearing seat of a small roller with little damage with the grinding method may be even less than one million tomans. Of course, this price includes the cost of materials (grinding), the cost of repairman’s wages, and the cost of payment. If the damage to the bearing seat is severe, it may be necessary to repair it by welding method. The cost of repairing the bearing seat with a welder is more. It may be up to 40 million tomans. Keep in mind that these prices are estimates. In the following, we will introduce the factors affecting the price.

Type and severity of injury

The type and severity of damage is the first and most important factor in determining the cost of repairing the bearing. It is natural that the more severe the damage to the bearing, the higher the repair cost.

Roller size and shape

You should definitely not expect that the cost of repairing a low-quality car is the same as the cost of repairing a luxury car. The same is the case with the rollers and their bearings. Larger and more complex rollers cost more to repair. Why? Because the number of these failures can be more and require more time.

Bearing type

The reasoning of this case can be considered exactly the same as the previous case. We said that the bigger the roller, the more complex the system is. This complex system includes the number of bellrings and their type and complexity. So, the type of bearing can have a great impact on the cost of repairing the bearing.

The cost of materials and repairman's wages

Note that the more quality material you use, the higher the cost. At the same time, the higher the expertise of the repairman whose knowledge you use, the higher the cost. Of course, the cost of materials and repairman’s wages are different in different regions of the country.

safety tips

In the industry, doing everything requires compliance with safety principles. This applies even to the simplest tasks. You know that the first principle in any work is safety. During the repair of the bearing seat, the safety points must be fully observed in order to prevent an unfortunate incident from happening. In this section, we examine some of these points. First, make sure to use proper safety equipment such as safety glasses, safety gloves, and safety shoes. Then note that before starting work, remove the roller from the machinery. Before that, make sure that the device is turned off. Also note that during grinding and welding or even polishing, be sure to have eye and face protection and safety clothing. By following these tips, you can continue your work safely.

Thank you for joining us in this article. As you have seen, in this article, we examined the repair of the bearings in the rollers. Also, we introduced suitable bearings for each type of activity and told you the cost of bearing repair. We hope that the material presented in this article has been considered and useful. Mabanapaya Industrial Group with expertise in this field is ready to help you dear ones. The effort of Mabanapaya Industrial Group is to provide you its services in the best way and with the help of the best specialists. You can contact us for more information and free consultation.