Imagine that you are working on the production line of industrial parts in a large workshop. With care and concentration, you check the parts one by one and if there is any defect, you remove it from the production line. You know that quality control of industrial parts is very important. If low-quality parts are produced, they may cause many problems for customers. For example, if a part of an industrial machine is produced with low quality, it may cause the machine to fail and cause a lot of damage. Quality control of industrial parts is a complex process that includes various steps. Today and in this article, we will examine the various stages of quality control of industrial parts and we will see the importance of this process for success in the market. So we suggest that you accompany us until the end of the article.

What is quality control?

Quality control of industrial parts is a process that is carried out in order to guarantee the quality of industrial parts and customer satisfaction. Of course, maybe before we want to give more explanations, you yourself know what this process includes. But it’s okay to say it again. In the quality control process, much attention is paid to the supply of healthy parts. In fact, it is not allowed to place defective parts and products next to healthy products. Of course, this work is also done in the initial production processes. In the initial processes, much attention is paid to the use of quality materials. Of course, only the points we said here are not included in today’s topic category. This topic has various processes that you will get to know today and in the Mabnapaya.

Quality control steps of industrial parts

The first step in quality control of industrial parts is to determine the quality criteria. Quality criteria specify what features a quality piece should have. These features may include dimensions, material properties, performance, and other features expected by the customer.

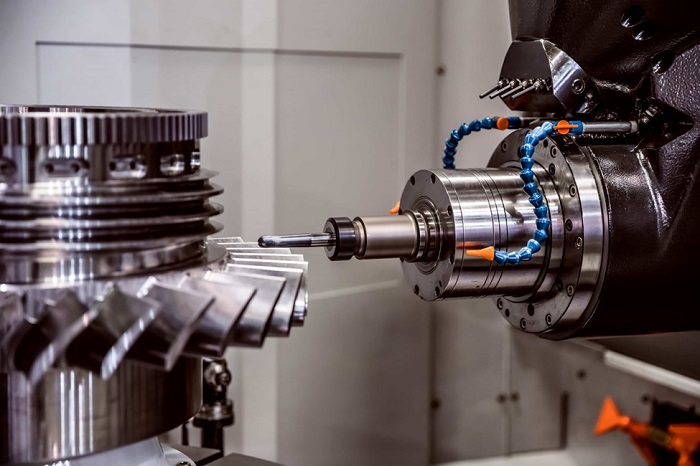

But after determining the quality criteria, the quality of the parts should be measured. To measure the quality of the parts, various tools such as calipers, micrometers, CMM machines, etc. are used.

Then, after measuring the quality of the parts, the measurement data should be analyzed. This helps to identify weak points in the production process.

After identifying the weak points in the production process, the necessary corrective actions should be taken. These measures may include changes in raw materials, production equipment or production methods.

Importance of quality control of industrial parts

Quality control of industrial parts is very important. This process helps to ensure product quality and customer satisfaction. Quality control of industrial parts brings the following advantages:

Reducing production costs

You know that one of the main goals of industrial units is to try to reduce production costs. But to achieve this goal, a series of activities must be done. Quality control of industrial parts helps to reduce production costs. This is due to the reduction of waste and repairs.

Increase Productivity

Increasing productivity is one of the most important goals that industrial workshops seek to achieve. Due to the increase in productivity, the net profitability of a workshop increases. Quality control of industrial parts helps to increase customer satisfaction. This is due to the customers’ confidence in the quality of the products.

Customer Satisfaction

Imagine that you once cooperated or bought a product from an industrial workshop. What makes you go back to them? Good quality that was presented to you the first time. Quality control of industrial parts helps to increase customer satisfaction. This is due to the customers’ confidence in the quality of the products.

Solutions to improve quality control

Quality control is a dynamic process that must be continuously improved. Manufacturers should always look for ways to improve their quality control process. This makes them able to update themselves in line with the world’s standards and as a result, they can provide better quality.

Production line employees play an important role in controlling the quality of industrial parts. In fact, it can be said that they play the main role. Therefore, they should be trained in quality control so that they can identify defective parts and prevent their production.

The use of advanced tools and equipment to measure the quality of parts increases the accuracy of measurement and helps to more accurately identify weak points in the production process. These tools are made according to the world’s standards and can help to improve the control process.

Using statistical methods to analyze quality data helps to identify weak points in the production process and allows the manufacturer to take necessary corrective actions in a scientific and accurate manner. In simpler words, this way you can fix the previous problems and take a step in the path of progress.

The importance of quality control in human life

Today, with the advancement of technology and the increase in the world population, the use of various industrial parts is increasing. Among these parts, we can mention metal parts, rubber parts, polyurethane parts, parts protectors, etc. What do we want to achieve by saying these things? You know that paying attention to the high quality of these parts is very important. For example, imagine a car wheel. What are the things in this system? Tires, bearings, brakes, etc. The correct functioning of these parts together can help the comfort of the teeth. Otherwise, it can cause confusion, confusion and restlessness. As a result, it is very important to pay attention to the production standards of industrial parts. Of course, we used this example for a car wheel. Imagine the same example for a complete car. Or even for other things. Now you understand the importance of this matter more easily.

quality control expert

But with all the explanations that have been given, it is not bad to talk a little about the quality control expert. In order for a person to work as a quality control expert, he needs to have the necessary education and skills. This degree must be obtained in the field of that industrial activity. For example, the inspector of a mechanic workshop must have expertise and education in the field of mechanics. Or, for example, in a casting workshop, the expertise of a metallurgical specialist should be used. The duties of this person can include testing and inspecting parts, handling complaints and fixing defects, ensuring quality and safety, and training to ensure product quality. Also, this person must have various skills, including scientific skills, written and oral communication, as well as the ability to do team work.

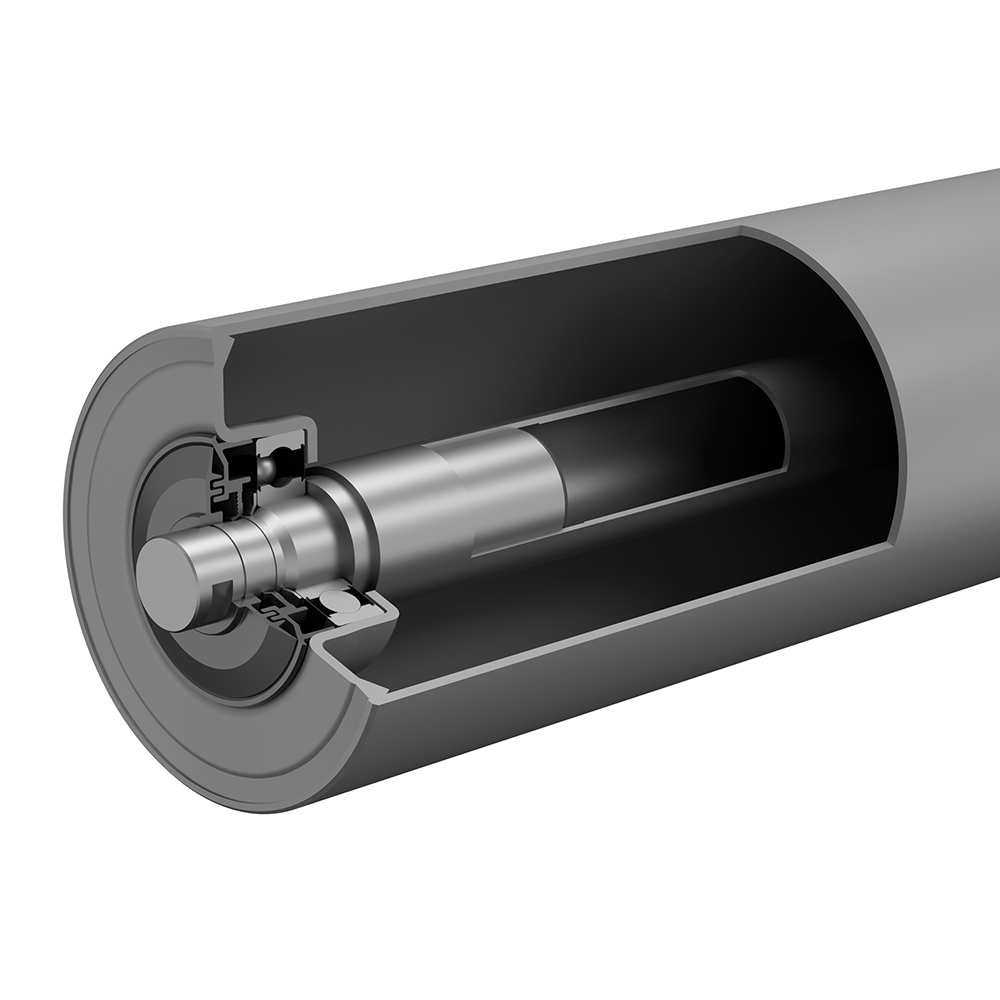

Thank you for your support, dear ones. As you have seen, in this article, we investigated the quality control in the production of industrial parts. We said that quality control of industrial parts is an important and necessary process that helps to ensure the quality of products and success in the market. This process includes various steps that must be done carefully. We also got to know a quality control expert and his job description. By following the recommendations presented in this article, the quality control process of industrial parts can be improved. We hope that the material presented in this article was useful to you. We operate as a specialized manufacturer and repairer of industrial rollers in Mabanapaya Industrial Group. Also, the production of rubber, metal and polyurethane parts is also done in our collection. You can contact us for more information and free consultation.