Mabnapaya Industrial Group Products and Services

We at Mabnapaya company produce and supply rubber and polyurethane products and parts, as well as manufacturing, coating, grinding and polishing services of various types of industrial rollers used in various industries, including textile, metal, cellulose and paper industries, food, printing and packaging and many other industries.

Our credit is your trust

We are proud that we have achieved high levels of product quality by relying on the creativity and abilities of our expert and experienced human resources and have provided services and products that meet the needs of customers and at the same time comply with professional and engineered principles. We have guaranteed the quality and stability of our services and products.

Mabnapaya Industrial Group, as one of the oldest companies in the production of rubber and polyurethane parts and industrial rollers, is active in the following fields by using the knowledge and experience of its experts and engineers:

Production of all kinds of rubber and polyurethane parts

At Mabnapaya, using quality raw materials and modern equipment, we produce all kinds of rubber and polyurethane parts in different sizes and shapes. These parts are used in various industries, such as automobile industry, food industry, textile industry and mining industry.

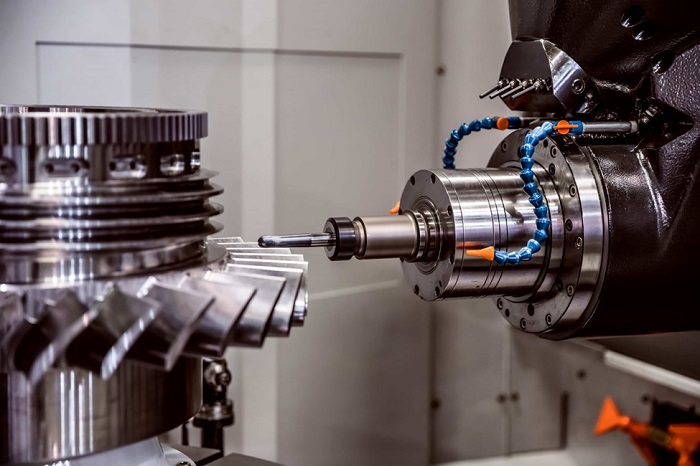

Manufacturing, coating, grinding and polishing of various types of industrial rollers

With advanced equipment, we produce various types of industrial rollers with high precision and quality. These rollers are used in various industries, such as food industry, textile industry, mineral industry and printing and packaging industry.

We at Mabnapaya Industrial Group, with more than 4 decades of presence in Iran’s industry, have gained valuable experiences in various fields and by cooperating with various industries, we have become well acquainted with the needs of our customers and have been able to provide products and services that suit these needs.

Among the business that Mabnapaya Industrial Group has acquired in these years, the following can be mentioned:

- Familiarity with the needs of different industries

- Mastery of today’s technologies

- Skill in producing high quality products

- Ability to provide after-sales service

These valuable experiences have made this company to become one of the leading companies active in the field of production of rubber and polyurethane parts and industrial rollers in Iran.

Mabnapaya Services

Stone and polishing roller

The purpose of this service is to improve the quality of roller surfaces and parts and increase their lifespan. Grinding and polishing the surfaces of rollers and parts make them smooth and polished and prevent wear and corrosion. This helps to improve the performance of rollers and parts and increase production efficiency. At Mabnapaya Industrial Group, we provide services to our dear ones by using modern and advanced grinding and polishing machines and relying on the ability of expert and experienced forces.

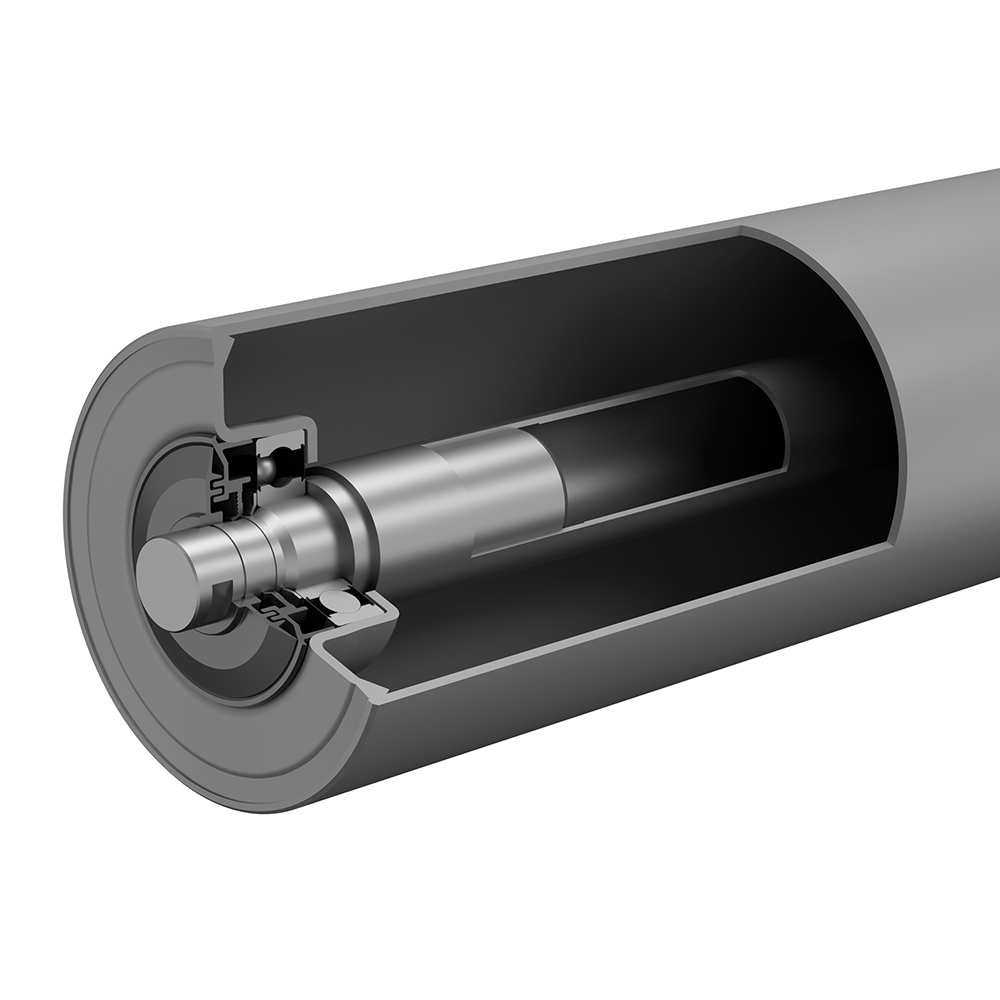

Replacing the roller shaft

A worn shaft may impair roller performance due to wear, corrosion, or breakage. Replacing the worn shaft with a new one will make the roller work properly and increase its life. Replacement includes operations such as separating the worn shaft from the roller, preparing the new shaft for installation, and installing the new shaft in the roller, which is done in the Mabnapaya industrial group using the most advanced equipment and the most experienced specialists of this service.

Repair of bearing retainer

If any problem is found in the bearing holder, it should be repaired or replaced immediately. This work will prevent damage to the roller and other parts of the device, and of course it should be done by professionals. Bearing retainer repair usually involves operations such as grinding, polishing, or welding. The purpose of bearing retainer repair is to restore its performance and lifespan.

Static roller balance

Static balancing of industrial rollers is a process in which rollers are balanced in terms of mass and mass distribution at rest. This is done to prevent vibration of the rollers during work. This is usually done using advanced devices that include an axis to position the roller and a set of sensors to measure the mass and distribution of the roller mass.

Mabnapaya Products

Rubber parts

Rubber parts produced in Mabnapaya Industrial Group are widely used in industries such as printing and packaging, automotive, food industry, etc. Flexibility, wear and corrosion resistance, impact absorption, friction reduction, vibration and vibration reduction, sealing, surface protection, etc. are the distinctive features of the rubber parts produced in the Mabnapaya Group factory.

Metal products

Metal products have properties such as strength, wear and corrosion resistance, and high electrical and thermal conductivity and are used in various industries. Metal molds are one of the most important products of this type and are used for shaping. Different types of metal can be used in the production of rollers and metal parts, and the choice of metal type depends on various factors such as the use of the part, environmental conditions, and budget limitations. You can get various metal products from Mabnapaya industrial group according to your conditions.

Polyurethane parts

Polyurethane is a synthetic polymer formed by the reaction of isocyanate and polyol and has properties such as flexibility, wear and corrosion resistance, and shock absorption. These parts are used in various industries and help to improve the performance of equipment and the safety of people.

Rubber rollers

A rubber roller is an industrial part made of rubber. This piece has an inner axle or tube covered by an outer layer of rubber. The inner shaft is usually made of steel, aluminum, or other strong and rigid material. The outer layer of rubber is usually made of rubber polymers such as polyurethane, EPDM, neoprene, or natural rubber. Rubber rollers are produced in different types, each of which has its own application.