Polyurethane parts

Polyurethane is a thermoset polymer that consists of a combination of two chemicals, diisocyanate and polyol. Diisocyanate is a reactive chemical that has two isocyanate groups. Polyol is a reactive chemical that has two hydroxyl groups.

Polyurethane is one of the most widely used polymer materials in the world. This substance consists of a combination of two chemicals, diisocyanate and polyol. Polyurethane exists in different types of solid, liquid and foam. Polyurethane parts are among the products made from this material. These parts are used in different industries and have unique properties and characteristics. The use of this material in various industries has increased due to its high properties and characteristics, especially its high endurance, and many factories have turned to the production and use of polyurethane parts. With these facts, we understand what a useful piece we are dealing with. Today, in this article, we will examine polyurethane parts. Then we will examine the uses and features of polyurethane in various industries. Follow us to the end.

What is polyurethane?

Polyurethane is a thermoset polymer that consists of a combination of two chemicals, diisocyanate and polyol. Diisocyanate is a reactive chemical that has two isocyanate groups. Polyol is a reactive chemical that has two hydroxyl groups. When diisocyanate and polyol combine with each other, a chemical reaction occurs between the two isocyanate groups and the hydroxyl groups. This reaction leads to the formation of a three-dimensional molecular network that determines the properties of polyurethane. Polyurethane exists in different types of solid, liquid and foam. I said that polyurethane is used in various industries. The substance that is finally obtained cannot be used immediately. First of all, you should know that its solid form is useful for use in industries. In the next step, you should know that the parts made of solid polyurethane will be practical.

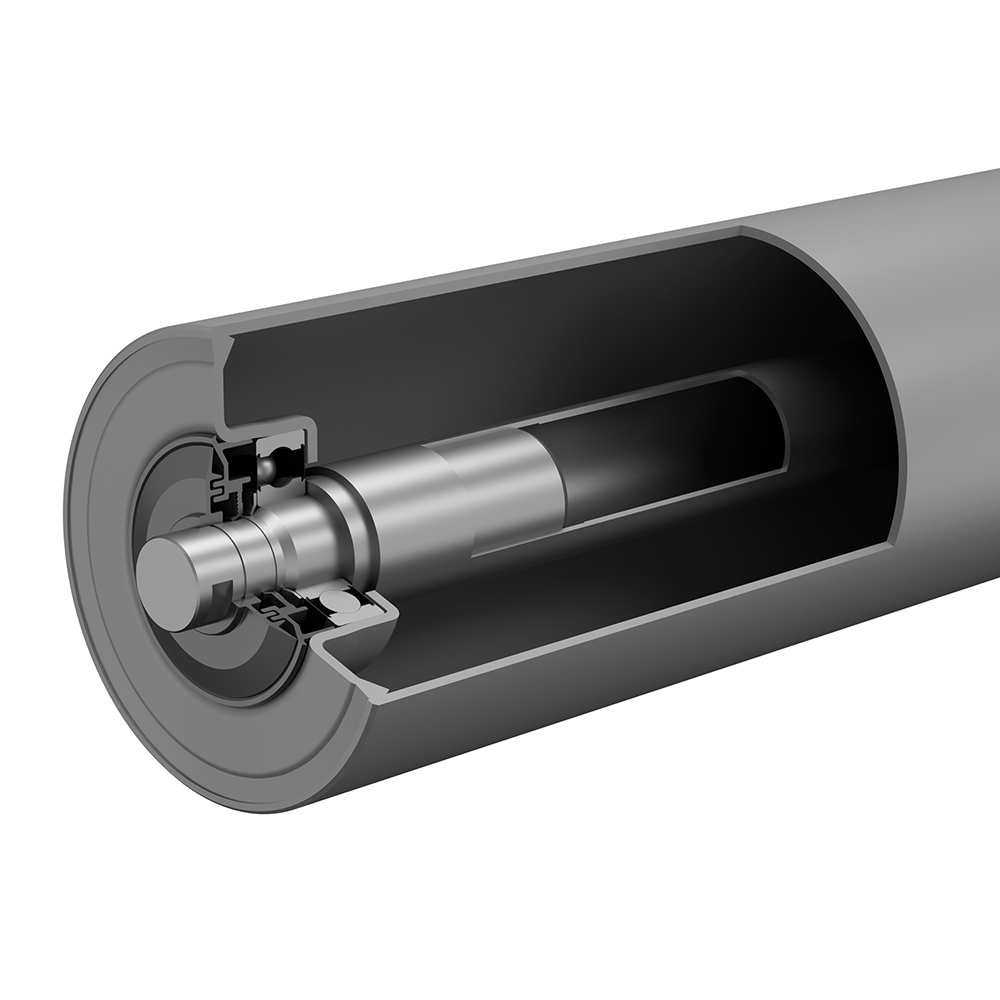

How to make polyurethane parts

These parts must be produced through a specialized and special process. In this section, we are going to check the production of these parts. Polyurethane parts are usually produced using injection molding. In this method, polyurethane is injected into a mold in liquid form. The mold has the shape of the desired part. After the injection of polyurethane, the mold is closed and the polyurethane hardens inside the mold. After the polyurethane hardens, the mold is opened and the piece of polyurethane is removed. In some cases, polyurethane parts are manufactured using the casting method. In this method, polyurethane is poured into a mold in liquid form. After the polyurethane hardens, the mold is broken and the piece of polyurethane is removed. After that, if the part is produced correctly, it can be said that the part is ready to be used in your desired activity.

Applications of polyurethane in various industries

We said earlier that polyurethane is used in various industries. What industries do we mean? Do not rush, we will tell you. Among the applications of polyurethane in the industry, the following can be mentioned:

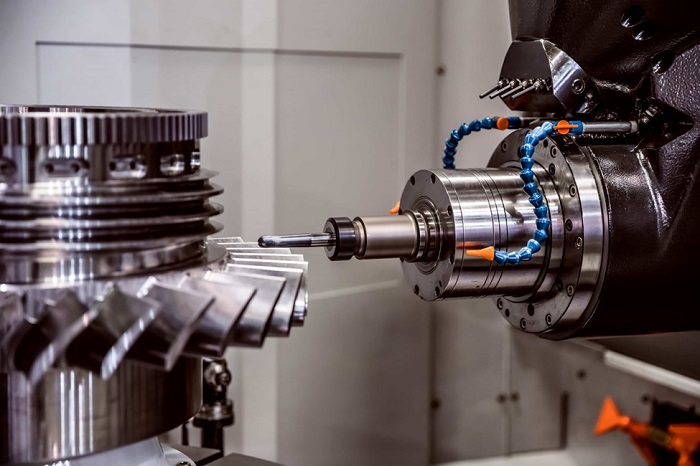

Automotive industry

Automobile manufacturing is one of the most important industries that many countries have gained access to. The acquisition of automobile technology by many countries has increased internal and external competition between them. For this reason, they always try to produce the best product using different tools. Polyurethane parts are widely used in automobile manufacturing. Among the polyurethane parts in the automotive industry, we can mention car body parts, car engine parts, and car interior parts.

construction industry

Due to the sensitivity of the construction industry, it is necessary to pay a lot of attention to the material we use in its construction. Sometimes small mistakes or deceptions made by a few builders cause big disasters to happen. Polyurethane parts are also used in construction. Polyurethane parts in construction include acoustic and thermal insulation, decorative parts, and industrial parts.

Packaging Industry

Packaging is usually known as the showcase of a product. But there are some products that need special packaging. Polyurethane parts are widely used in packaging industries. Among the polyurethane parts in the packaging industry, we can mention food packaging, industrial packaging and pharmaceutical packaging. Polyurethane’s high resistance to heat and humidity has made this product widely used in this field.

Agriculture industry

In countries where agriculture is popular, farmers are treated a lot. Of course, the meaning of the word handling is to try to make their work process easier. For this reason, tools should be provided to them so that they can work easily. Polyurethane parts are widely used in agricultural industries. Polyurethane parts in agricultural industries include agricultural machinery parts, irrigation parts, and greenhouse parts.

Medical industry

Medical science is a science that people always owe their lives to. For this reason, many activities are carried out to put this science on the path of progress. Polyurethane parts have many applications in the medical industry. Among the polyurethane parts in the medical industry, we can mention medical prostheses, medical equipment parts, and laboratory parts, which happen to be part of the widely used parts in this field.

Other industries

Packaging is usually known as a product’s vitzen. But there are some products that need special packaging. Polyurethane parts are widely used in packaging industries. Among the polyurethane parts in the packaging industry, we can mention food packaging, industrial packaging and pharmaceutical packaging. Polyurethane’s high resistance to heat and humidity has made this product widely used in this field.

Properties and characteristics of polyurethane

With so many definitions of polyurethane, it is necessary to introduce its properties and characteristics to you dear ones. Polyurethane has unique properties and characteristics that have made this material to be used in various industries. In the rest of this section, we are going to examine these wonderful features and properties.

Polyurethane has high resistance to wear and corrosion. This has caused polyurethane to be used in industries where parts are subject to wear and corrosion. Note that these parts can be produced with different resistances. As the weight of the work increases, it is necessary to increase the strength of the piece.

It is natural that when a part is resistant to wear and corrosion, it is also resistant to shocks. Polyurethane has high impact resistance. This has caused polyurethane to be used in industries where parts are exposed to impact. One of these activities is forklift wheel. Yes, sometimes wheels are used for forklifts that are made of durable polyurethane.

Polyurethane has high resistance to heat. This has caused polyurethane to be used in industries where parts are exposed to heat. For this reason, polyurethane and related parts are sometimes used in industries that may deal with furnaces and other high-heat appliances. Ovens and even microwave ovens can be considered as simple examples.

We said that polyurethane is used in the packaging industry. If you pay attention, it is written on most of the packages that it should be kept away from moisture. Polyurethane has high resistance to moisture. This issue has caused polyurethane to be used in industries where parts are exposed to moisture. Including the packaging of the various items we mentioned.

It is true that polyurethane itself is made from many chemicals. But this does not mean that it shows weakness against other chemicals. Polyurethane parts have a high resistance to other chemicals and simply do not allow chemicals to penetrate.

Let us first say what is meant by the word elasticity. The root of the word elastic is the word elastic. You are definitely familiar with the word elastic. In fact, elastic refers to the flexibility of objects. Now, in our discussion, it should be said that polyurethane has high elasticity. This has caused polyurethane to be used in industries where parts require flexibility.

The texture of the parts made of polyurethane is such that they have little weight. In fact, it can be said that the ratio of the mass of the object to the volume of the object is low. Now what does this mean? In fact, we mean that the parts made of polyurethane, despite having high resistance and hardness, have low density. For this reason, polyurethane should be used in industries that require light weight parts.

The cost of making polyurethane parts

In industry, parts are made in several basic ways. Metal and plastic. Making parts using polyurethane is another one of these forms. But the question that always exists for industrial units is the cost of manufacturing parts. Of course, this concern is also natural. Because all businesses try to reduce additional costs for more profit. But how much does it cost to produce polyurethane parts? The cost of manufacturing polyurethane parts depends on various factors, including the type of part, the dimensions of the part, the amount of raw materials required, and production costs. In general, the cost of manufacturing polyurethane parts is lower than metal parts and other materials. That is why, in recent years, many industrial units have started using these parts.

A few points about polyurethane

In this section, we are going to tell you some tips regarding the time of dealing with polyurethane parts. Knowing these tips can help you avoid potential risks. Of course, it does not threaten you with many risks when dealing with polyurethane. But knowing these points is not bad.

- Polyurethane is a recyclable material. This is an advantage rather than a warning. So you can still recycle a piece when it fails.

- Polyurethane may contain allergens, so care should be taken when working with it. Of course, don’t worry at all. This sensitivity is for people who have physical weakness and physical problems. This issue is solved by using a mask and work gloves. Of course, this does not mean that healthy people do not take precautions. Everyone must observe safety precautions while doing industrial activities.

- Unfortunately, polyurethane acts like a catalyst in a fire. what does it mean? It means that he will do his best to help the fire. Although polyurethane parts are resistant to heat, polyurethane may be exposed to dangerous fires, so proper safety equipment should be used when working with it.

Thank you for joining us in this article. You have seen that in this article we have thoroughly reviewed and introduced polyurethane. We also examined its manufacturing method, characteristics and properties, as well as the uses of polyurethane parts in the industry. We hope that the content presented in this article has been liked by you dear ones. It is necessary to repeat that polyurethane parts are used in various industries due to their unique properties and characteristics. With the ISO 9001 certificate, Mabanapaya Industrial Group is proud to announce that it specializes in the production of polyurethane parts. Dear ones, if you want to use these parts, just contact us. The experts of our collection are ready to answer you from Saturday to Wednesday from 8:30 to 17:00.