In today’s world and with the development and advancement of technology in various industries, many solutions have been created to advance various goals. You know that having smooth and polished parts can help devices and parts work better. This good performance can have many benefits, including the absence of device failure, increasing efficiency, and other benefits. There are different ways to smooth and polish parts. Grinding is a machining method in which a grinding wheel with an abrasive surface is used to remove chips from the surface of the workpiece. Grinding is an abrasive process that is used to create a smooth, precise and quality surface. This process is used in various industries, including the production of auto parts, industrial equipment, tools, etc. Today, in this article, we are going to introduce and teach grinding. Stay with us until the end.

What is grinding?

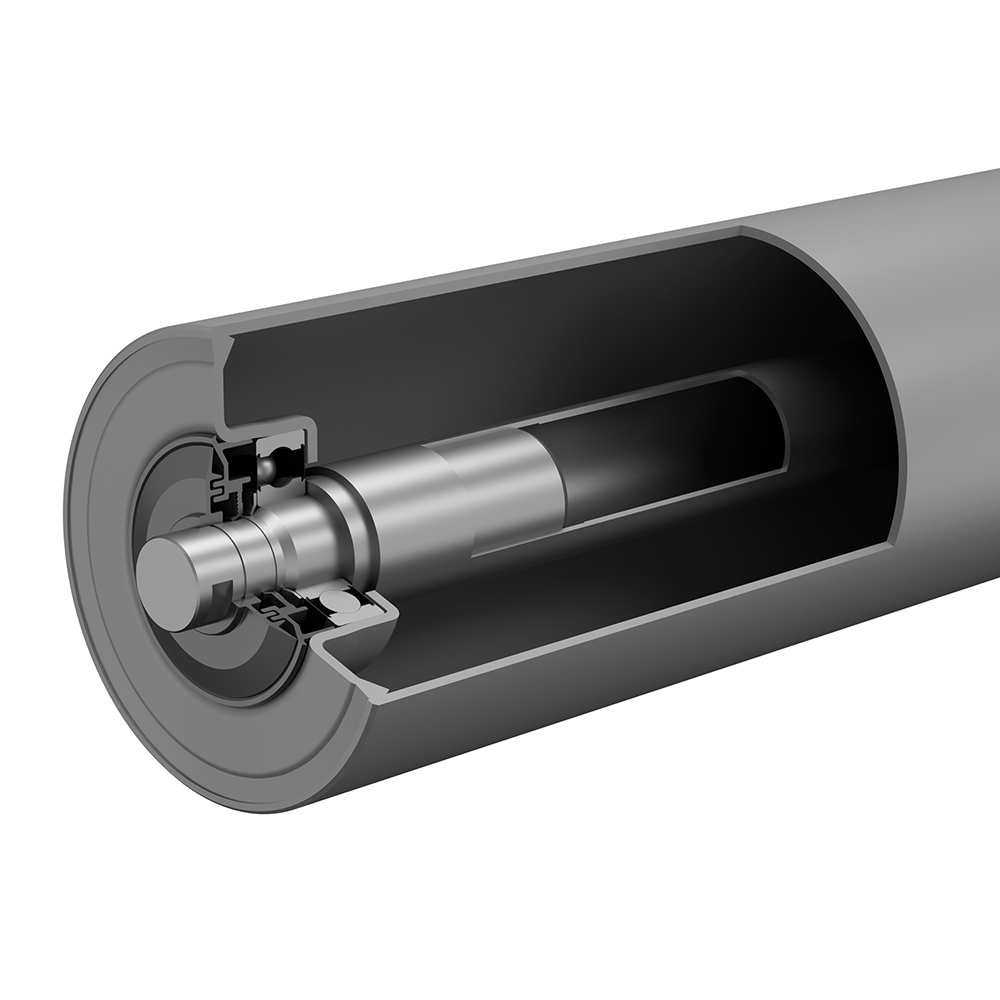

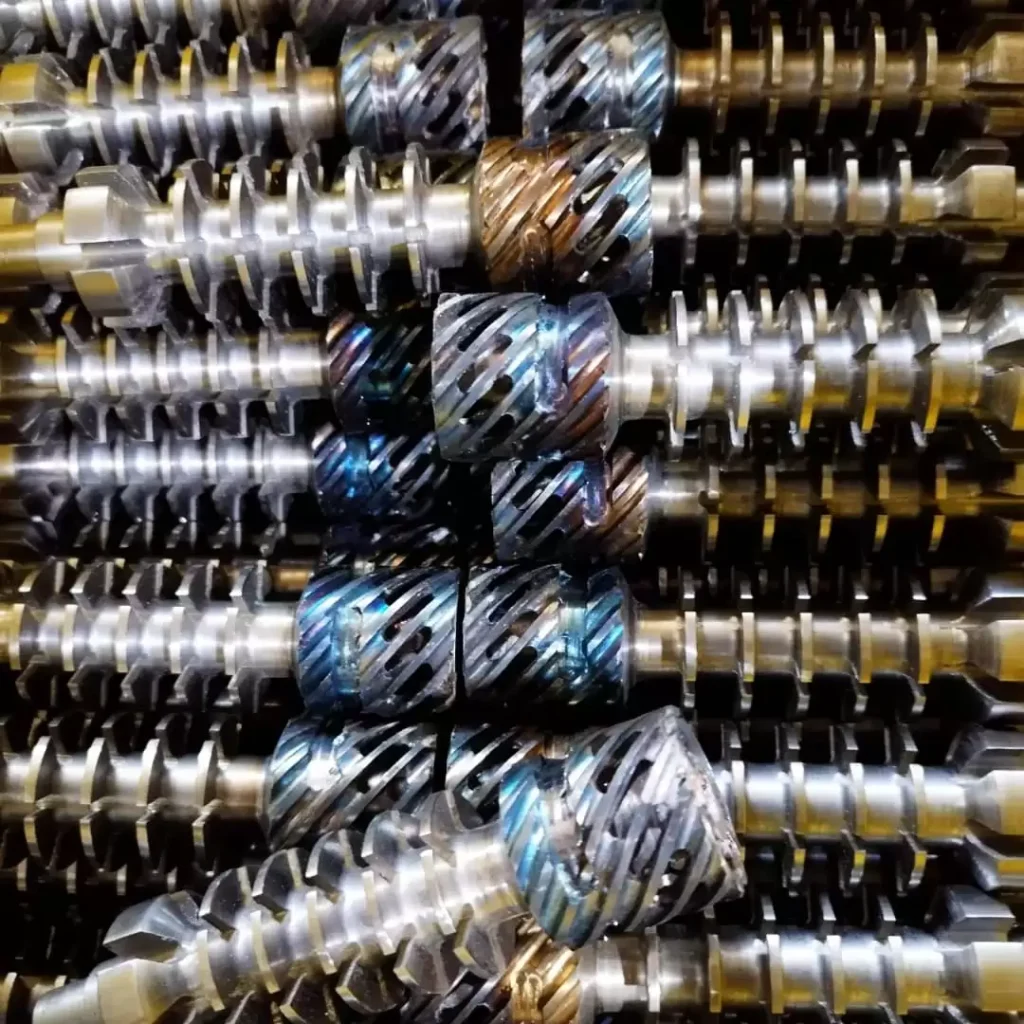

A process in which a grinding wheel with an abrasive surface is used to remove chips from the surface of the workpiece. Grinding stones are made of abrasive materials such as diamond, aluminum oxide, ceramic, etc., which are produced in spherical, conical, flat, etc. in different types. In simpler words, in this process, sandpapers and polishes are used the most. Of course, you should keep in mind that it should be done according to the type of piece. Let’s put it a little simpler. Grinding can be done by flat, cylindrical or angular methods. As a result, with these names that we have seen, we must choose the appropriate type of grinding according to the shape of the piece. The grinding process can be done in a better way by using high-quality sandpapers and high-quality gilans. Do not forget that skill and expertise are required for this work.

Grinding applications

Perhaps in the previous two parts, we have sufficiently understood the benefits of this process. The first and most important advantage of this method is creating a smooth and polished surface on the parts. The second feature, which is worth investigating, is creating high accuracy in the measurement and geometry of the work piece, which has a great impact on the performance of the devices. In this method, by removing the shavings from the work surface, we lighten and optimize the piece. Grinding method can also be used to repair worn parts and create complex shapes on different parts. We are ready to carry out the grinding process on different parts by taking advantage of the expertise of skilled craftsmen in the base collection. This work is done by the most advanced equipment so that the smallest disturbance in the work process does not take place.

The difference between grinding and roller polishing

Grinding and roller polishing are both abrasive machining methods used to create a smooth and polished surface. Roller polishing is one of the most common methods of smoothing and polishing surfaces, which is widely used today. However, there are differences between these two methods, including the following:

In grinding, the grinding wheel is in direct contact with the surface of the workpiece, while in roller polishing, the abrasive rollers are in contact with the surface of the workpiece.

In grinding, the grinding wheel can move in different directions, while in roller polishing, the rollers usually move in one direction.

Grinding is usually used to produce a high precision in the measurement and geometry of the workpiece, while roller polishing is usually used to produce a smooth, polished surface with less precision.

Grinding training

But now let’s go to the part of the article that we promised. To do this, it is necessary to be familiar with the principles and safety tips of this process. Also, you need to be able to choose the right grindstone for the workpiece. Of course, keep in mind that just by reading the following content, you will not be qualified to perform the grinding process alone. Doing this process requires years of experience and expertise in this field or similar activities. In the following, we will provide a brief tutorial on this process.

levels

Part surface preparation

The first and most important step to perform this process in an easy way is to clean the surface of the part from additional and disturbing pollution. At this stage, you should clean the surface of the workpiece from any contamination and rust. Also, you may need to prepare the workpiece using pre-polishing stones. In this way, the grinding process is done more correctly and easily.

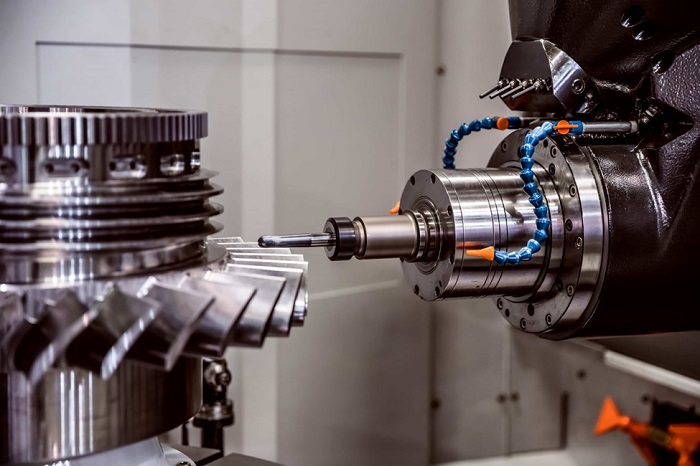

Main grinding

This stage is the beginning of working with the grinding machine. It is true that the name of this stage is the main grinding, but it is not the final stage. In this step, you use the main grindstone to remove chips from the surface of the workpiece. This will prepare your piece to move on to the next step. Note that at this stage you should use high-quality sandpapers and polishes.

Final grinding

But after doing the above tasks and processes, it is time for the final grinding. This requires the use of high quality sandpapers and sandpapers. If you don’t use a high-quality product, the surface of the parts will not be polished well. In this step, you use the final grindstone to create a smooth, polished surface.

safety tips

This process requires compliance with a series of safety precautions, which is not very difficult or complicated. In the following we will examine some of these cases.

Wear safety glasses to protect your eyes from flying chips.

Wear safety gloves to protect your hands from cuts and burns.

Before starting, make sure the device is set up correctly.

Use loose and comfortable clothes to avoid getting stuck in the machine.

Grinding cost

The cost of this process depends on various factors. Undoubtedly, it is not possible to specify a fixed price for this specialized process. This cost depends on various factors such as the type of grinding stone, the size of the work piece, the required accuracy, etc. In general, the cost of grinding small and simple parts is lower than large and complex parts. Of course, this can be a natural thing. We at Mabanapaya Industrial Group are ready to do this process on the parts for you with the best price and the best quality of work.

Thank you for joining us in this article. You have seen that in this article we reviewed and introduced and taught grinding. We said that it is an important and practical process in various industries. By learning the principles and safety tips of this process, you can safely and accurately stone the parts you need. We hope that the content presented in this article was useful for you. It is also hoped that you will stay away from the possible risks of industrial activities by observing safety tips. With the ISO 9001 certificate and the use of the best and most up-to-date devices, Mabanapaya Industrial Group is ready to provide grinding and roller polishing services for you. You can contact us for more information and free consultation.