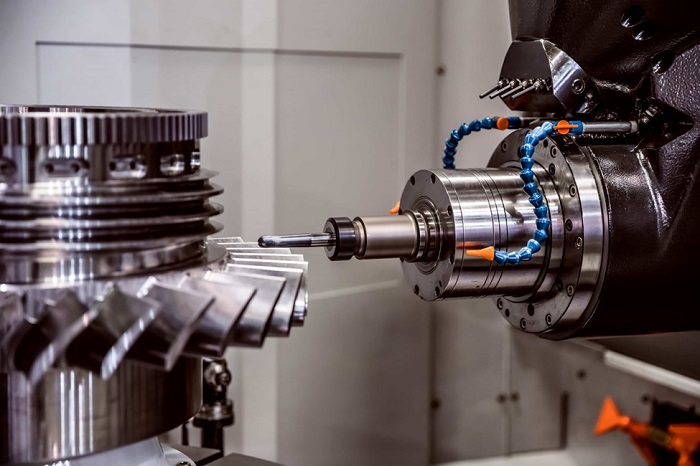

Metal parts are the most widely used elements in various industries. Everywhere you look, you see the presence of small and large metal pieces. Houses, cars, electric light poles, etc., all have a colorful role of metals. This is enough to understand the importance of these elements. This high use of metals causes that there are many solutions to protect them. Due to their properties, metals are more exposed to corrosion, damage and oxidation. One of the ways to protect these parts is to use polyurethane coating. Polyurethane is one of the widely used materials in various industries. This material is used in various applications due to its unique properties. Using polyurethane coating on metal parts can bring many advantages. Stay with us.

What is polyurethane?

First, it is better to define what polyurethane is? Polyurethane is a synthetic polymer that is formed by the reaction between two chemicals called isocyanate and polyol. Polyurethanes have different mechanical and chemical properties that make them suitable for different applications. These coatings do not conduct electricity and heat. For this reason, they can be easily used on metal parts. But the features of polyurethane are not only limited to this non-conductivity of electricity and heat. This material has other features that make it widely used. Among the features of polyurethane, the following can be mentioned:

- Ability to resist acids and bases

- High wear resistance

- flexibility

- High resistance to corrosion

- Ability to withstand high temperatures

Applications of polyurethane

Polyurethane has many properties that we said in the previous section. You are also aware of the importance of metals in various industries. In fact, we can say that wherever we see the presence of metals, we can also use polyurethane. Of course, this does not mean that polyurethane is used only in the presence of metals. These materials can generally be used in various industries. Among these industries, the following can be mentioned:

construction

automobile manufacturing

Food industry

petrochemical

Oil and Gas

Medical industry

Advantages of using polyurethane coating on metal parts

With all that said, it is natural that using these coatings on metal parts has many advantages. If you are also interested in knowing this, stay with us. The advantages of using polyurethane coating on metal parts are as follows:

Polyurethane is a material resistant to wear and corrosion. Using polyurethane coating on metal parts can prevent the wear and corrosion of metal parts and increase their lifespan. This is exactly what the devices or elements that work using these parts need. The need for early replacement of metal parts can cause disruption and increase the consumption costs of industrial units.

One of the things that workshop owners are always looking for is cost reduction. The same is true in the field of using different parts, especially metal parts. The use of polyurethane coating can reduce the maintenance costs of metal parts. This is due to the increase in the life of metal parts.

Polyurethane is a shock absorbing material. Using polyurethane coating on metal parts can prevent vibrations and impacts on metal parts and improve their performance. So, now you know that apart from taking care of the metal body, these coatings also affect their performance.

We said that metals have the property of conducting heat and electricity. These properties can be dangerous for people who are working with these parts. In fact, failure to observe safety precautions can cause an accident. Using polyurethane coatings can prevent such cases from happening. Because these coatings do not have the ability to transfer heat and electricity. So add this to other properties of polyurethane.

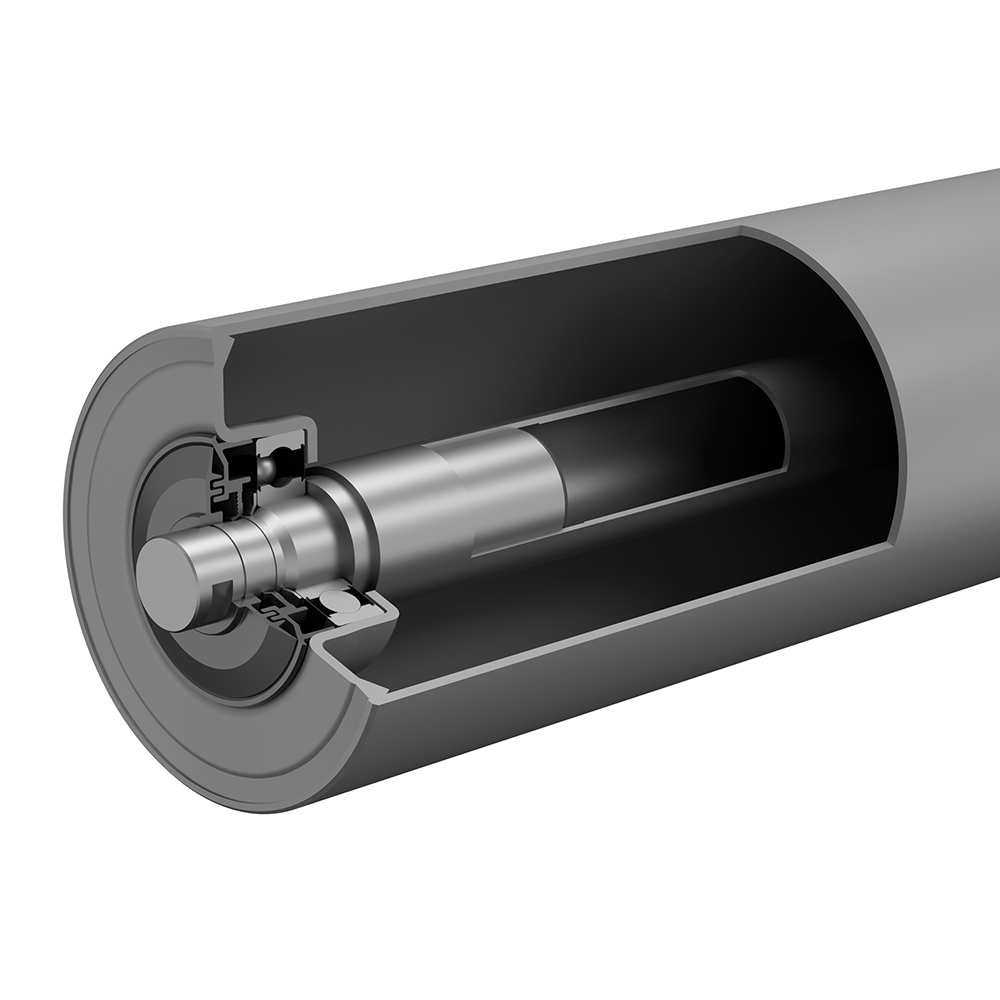

Using polyurethane coating on the roller

For many people whose activities are related to rollers, the question arises whether it is possible to use polyurethane on different rollers, such as industrial, agricultural, printing, etc.? Yes, polyurethane coating can be used on industrial rollers. These coatings have many advantages that can help improve the performance and longevity of the rollers. Among the advantages of using polyurethane coating on industrial rollers, we can mention increasing the lifespan of the roller, improving the working process of the roller, reducing the costs of maintenance and repair of the roller, and also increasing the safety of the roller devices during work.

Why should we use polyurethane coating on rollers?

Due to its resistance to wear and corrosion, the polyurethane coating can prevent the rollers from being damaged and increase their lifespan. Also, these covers can prevent vibrations and impacts on the rollers and improve their performance. In addition, the polyurethane coating can reduce the noise of the rollers and increase the safety. Industrial rollers are used in various industries, including food, textile, printing, and packaging industries. Using polyurethane coating on industrial rollers in these industries can bring many benefits. For this reason, industrial experts advise to use polyurethane a lot. Of course, this use must be appropriate.

The cost of using polyurethane coating on metal parts

Of course, a fixed price cannot be considered for polyurethane parts. The cost of using polyurethane coating on metal parts depends on various factors, including the type of polyurethane used, the dimensions and size of the metal part, and the production method of polyurethane coating. In general, the cost of using polyurethane coating is relatively affordable and can reduce the maintenance costs of metal parts. Considering all these things, a relatively accurate price can be considered for these covers. We at Mabanapaya Industrial Group are ready to offer you these covers with the best price, which are also of high quality.

Thank you dears for staying with us until the end of this article. As you can see, in this article, we reviewed and introduced polyurethane, polyurethane coating and the benefits of using it on metal parts. We said that using polyurethane coating on metal parts can bring many advantages. These coatings can prevent wear and corrosion of metal parts and increase their lifespan. Also, they can improve the performance and safety of metal parts. We hope that the presented content will be useful for you and you will like it. Mabanapaya Industrial Group is ready to provide the best polyurethane coatings to the applicants by having the ISO 9001 certificate as well as using modern and high quality equipment. You can contact the experts of Mabnapaya Industrial Group for more information.