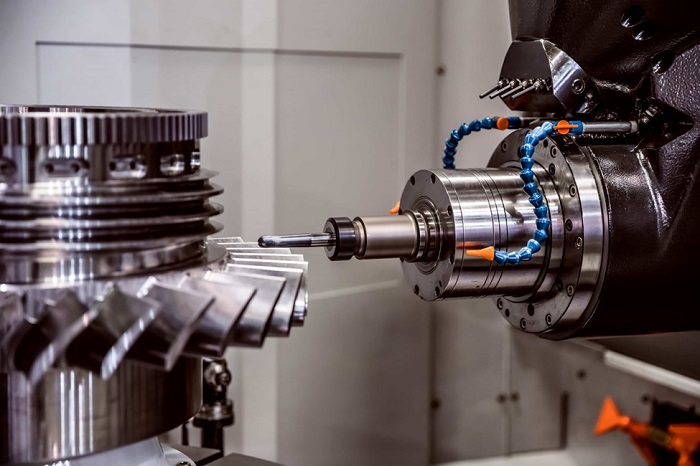

Certainly, one of the questions that have been in everyone’s mind since childhood is how to make paper. Maybe this question is still unanswered for many people. Paper is one of the most important human products that is used in various industries such as printing, packaging, stationery, etc. Paper production is a complex process that requires various equipment and machinery. One of these equipments is the roller, which plays an important role in paper production. But can any roller be used to make paper? Definitely not. You know that there are different types of rollers and they are used in different industries. The same thing is true in paper making. It means that special rollers need to be used in making paper. Today, in this article, we are going to introduce the types of rollers used in paper making.

paper making

Paper making is one of the most important industries in the world, which plays an important role in the economy and human life. This industry uses wood as its main raw material. Wood is turned into pulp in different ways, and then this pulp is turned into paper in special machines. This industry was invented in China for the first time in history. By using the wood of special trees, the Chinese were able to achieve the technology of making paper. The Chinese use wood from trees such as pine, fir, beech, oak, etc. in the production of paper. These trees have characteristics that are suitable for paper production. For example, these trees have long and strong fibers that make the paper produced from them strong and durable. But the issue of making paper does not end here. Follow us to provide you with more information.

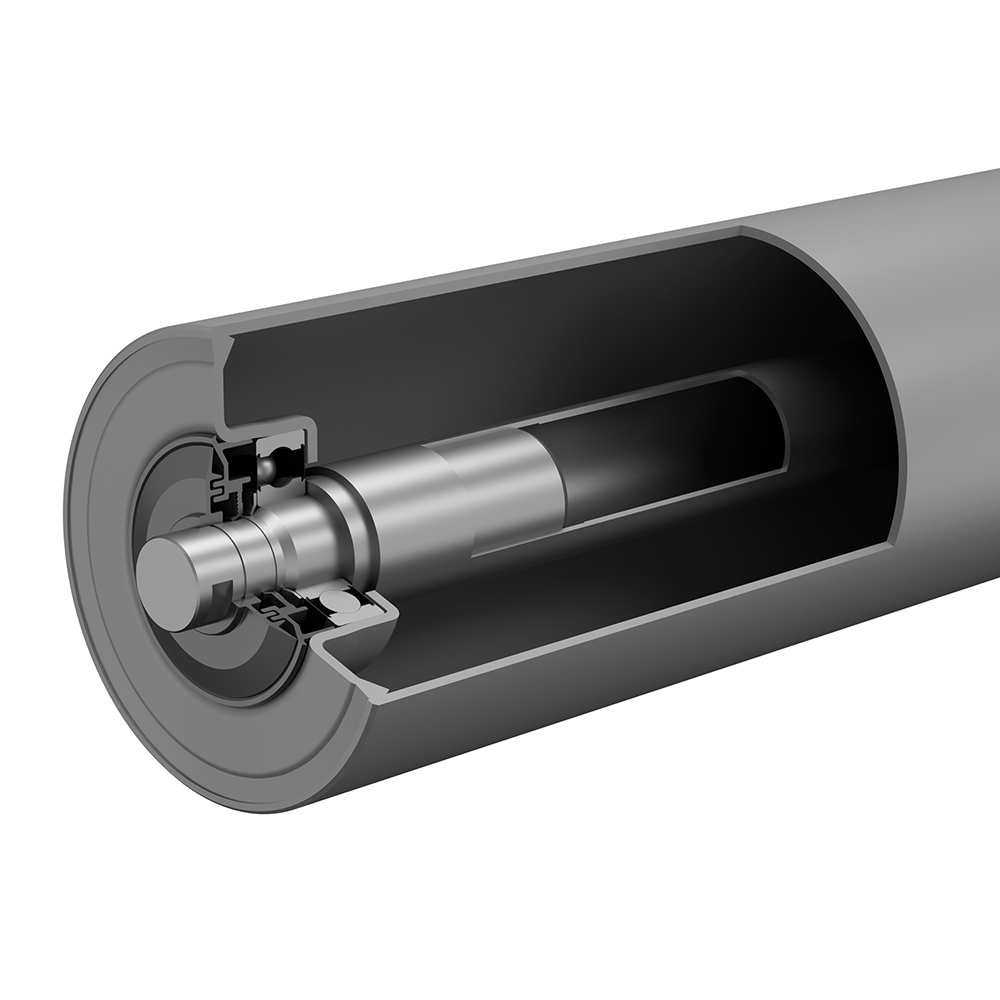

What is a roller?

In general, a roller is a cylindrical object, usually made of metal, wood or plastic. Rollers are used in various industries. In paper making, rollers are used to perform various tasks such as pulp compression, pulp transfer, paper drying, etc. All rollers consist of three main parts. The first part is the roller body. But the second part is the roller shaft, which is responsible for working the roller. The third is the bearing, which is responsible for the correct connection between the roller shaft and the roller body. Note that the malfunction of any of these parts can disrupt the working process of a roller system as a whole. Stay with us. In the following, we will examine the types of rollers in paper making.

Types of rollers in paper making

In paper making, we need to have five types of special rollers to make paper. In the following, we will examine these five rollers in the order of the performance stages together.

In the first step of paper production, we need to use felt and wire rollers. These rollers consist of two parts: flat and wire. Felt has a soft and spongy surface that is responsible for absorbing water from paper pulp. The wire has a hard and rough surface that is responsible for compressing the paper pulp.

These rollers are used to apply sizing materials on paper. Now, you may ask, what are the sizing materials? For example, you may have seen waterproof and stain-proof papers. Sizing materials make the paper waterproof and stain-proof. Press size rollers are usually made of soft and flexible materials. This allows them to do their work without damaging the texture of the paper.

Now it’s time to examine the third type of roller in paper making. This roller can actually be considered the most active roller in the paper making process. The press roller is used for optimal compression of paper in different stages. Using this roller helps the paper to have an even and smooth surface. These rollers are usually made of hard and strong materials so that they can withstand a lot of pressure.

In the final stages, it is time to use another type of roller, which plays an important role in order to obtain a good paper. The suction roller helps the paper reach a dry and rough texture inside and on the sides.

Now it’s time to check the last type of roller used in paper making. First of all, we must say that these rollers are used to dry and absorb the moisture present in the paper. These rollers have holes that allow the air to easily escape from the paper. This makes the paper dry faster.

Paper making process

As you can see, papermaking is a precise and orderly process that needs to be done with due care. In this section, we are going to examine this process. The steps to prepare the paper are as follows.

Wood preparation

The first step in paper making is wood preparation. We said earlier that the wood of trees such as pine, fir, oak, etc. is used in making paper. Wood is prepared in various ways, including sawing, chopping and pulping.

Paper pulp production

The second step in the paper making process is pulp production. It should be noted that this dough is not too wet or dry. Otherwise, quality paper will not be obtained. Paper pulp is produced through chemical, mechanical and thermal processes.

Pulp compression

In the third step of paper production, paper pulp is compressed in special machines to form a thin sheet. It should be noted that the thinness of these pastes should not be too much. Because in this case, the paper will find a very vulnerable texture.

Add sizing material

We mentioned earlier what materials are called sizing materials. But it’s okay to say it again. Sizing materials are materials that add properties such as waterproofing or stain resistance to paper.

Dry the paper

After doing all the above steps correctly, we are close to the final production of paper. When the above steps are done completely, it is time to dry the papers. After the papers are completely dry, the paper is ready.

paper cut

When the final paper is produced and comes out of the machine, we see it in the form of large sheets. At this stage, we should cut the paper with special cutters and make it ready for printing or other activities.

You have seen that in this article we examined the paper making process and the rollers used in paper making. Note that this process is a completely engineered process and to do it, you need to have healthy and up-to-date devices. We said that rollers play the main role in paper production. Paying attention to the health of the rollers makes the papermaking process to be done correctly and regularly. It is worth noting that because the rollers work for regular hours, it is necessary to carry out necessary maintenance and services on them regularly. We at Mabanapaya Industrial Group are ready to help you with ISO 9001 certification and expertise in the production and repair of all kinds of rollers. You can contact the experts of Mabanapaya Group for more information.