Paying attention to maintaining the health and safety of surfaces in industrial activities is one of the most important tasks that must be done. In addition to maintaining the high efficiency of the complex, this work can also help industrial groups a lot from an economic point of view. There are many ways to resist different parts and surfaces, especially metal. Such as bumpers, plastic covers, polyurethane covers, etc. But another way to protect different parts and surfaces is to use rubber lining. Rubberlining is a protective coating made of rubber and used to protect metal surfaces from corrosion, wear, impact, and other damage. This coating is commonly used in reservoirs, pipes, tanks, and other industrial equipment. Today, in this article, we are going to review and introduce rubber lining. So don’t miss this article and stay tuned.

What is rubber lining?

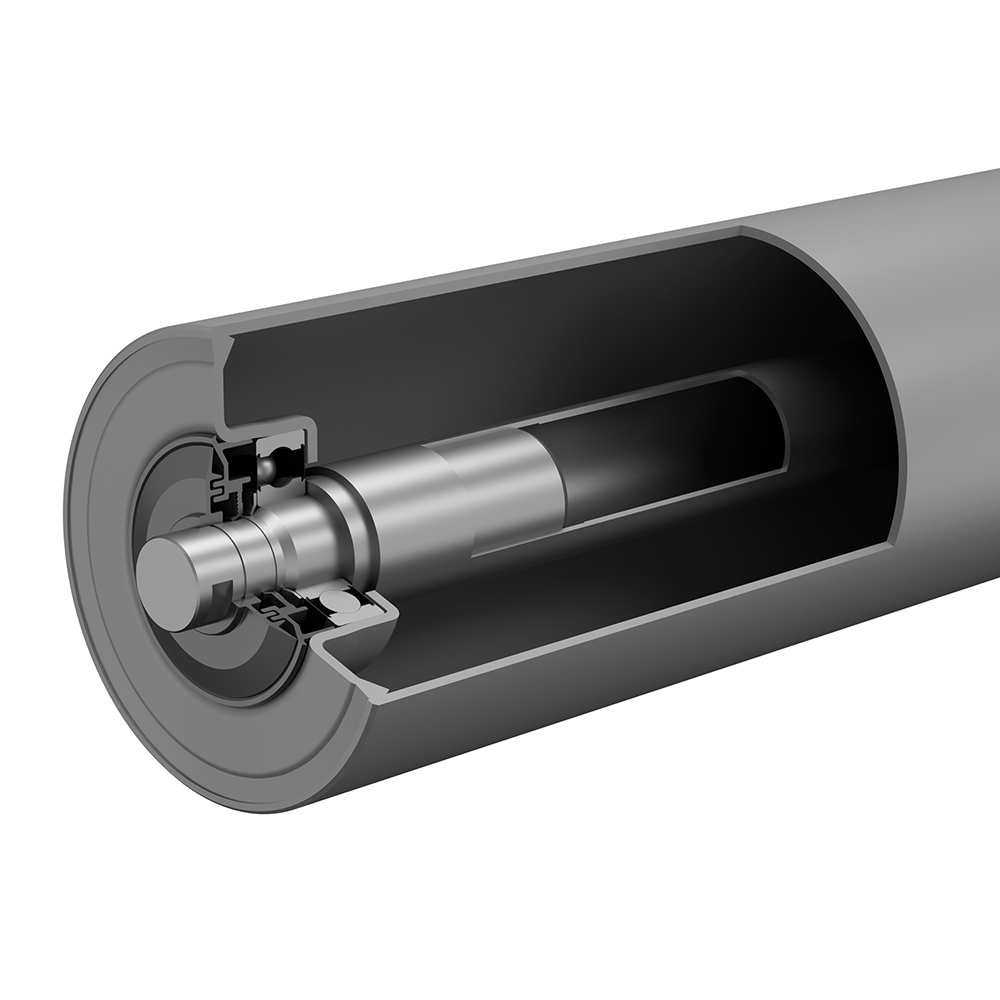

We said that rubber lining is a protective coating made of rubber and applied as a sheet or powder on metal surfaces. This coating is usually attached to the metal surface using heat or glue. Rubber lining consists of two main layers. The bottom layer, which is usually made of natural or synthetic rubber, is responsible for connecting the coating to the metal surface. But the second layer is the top layer, which is usually made of synthetic rubber and is responsible for protecting the metal surface. The use of quality rubber lining means that there is no longer any worry about damaging the metal surfaces and the operators can continue their work safely.

Advantages of using rubber lining

Rubberlining has many advantages that have made it a popular method of protecting metal surfaces. Among the advantages of using rubber lining are the following:

Rubber is a very corrosion resistant material and can protect metal surfaces against a wide range of corrosive substances. As a rubber protector, rubber lining can also resist corrosion from metals.

One of the things that always shortens the life of metal parts is their wear. This product is a very wear-resistant material and can protect metal surfaces from wear caused by the flow of fluids, solids, or other factors.

In addition to the things mentioned above, rubber lining also has impact properties. At all, one of the main properties of this element is this property. Rubber is a very impact resistant material and can protect metal surfaces from damage caused by impact or shock.

You know that metal parts are conductors of electricity and heat. Materials should be used on them to prevent the transmission of these currents to harm people or even other devices. Rubber is an excellent thermal and electrical insulator and can protect metal surfaces from heat or electrical transfer.

Rubber lining is a rubber material. Rubber is a fire retardant material and can protect metal surfaces from fire.

Applications of rubber lining

Certainly, an element with all these properties that we have said can have many uses. Rubber lining has wide applications in various industries. Among its uses, the following can be mentioned:

Chemical tanks

Rubber lining is used to protect chemical storage tanks against corrosion and wear. Due to the sensitivity that exists in chemical industries and activities, it is necessary to use suitable and quality materials in this field.

Material transfer pipes

These pipes need to be protected by a suitable cover because they are transporting dangerous substances under high pressure. This coating should be able to prevent corrosion, wear and impact on these pipes.

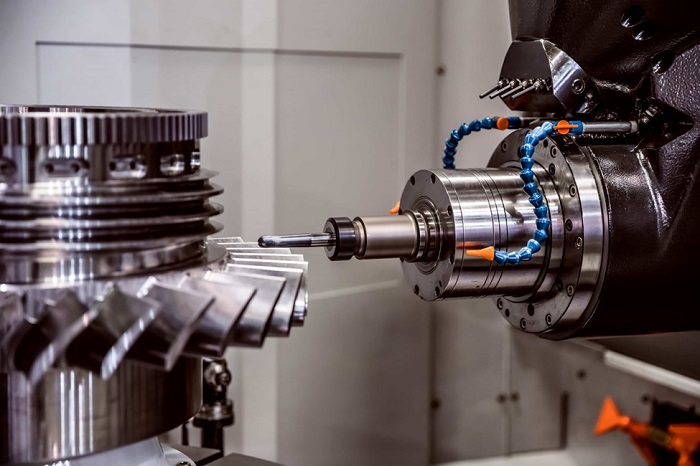

Industrial equipment

Rubber linings are used to protect industrial equipment such as valves, pumps, and other equipment from corrosion, wear, and other damage. These components need to be protected due to the heavy activities they perform.

Consequences of not using rubber lining

But what are the consequences of metal surface wear? This product is an effective way to prevent metal surface wear. Rubber is a very wear-resistant material and can protect metal surfaces from wear caused by flowing fluids, solids, or other factors. These wears can reduce the useful life of the device, reduce fluid flow and increase leakage. Rubber lining can greatly increase the useful life of equipment and avoid maintenance costs. Rubber lining is applied on the metal surface in both sheet and powder forms. In the sheet method, a pre-cut rubber sheet is placed on a metal surface and bonded to the surface using heat or glue. In the powder method, rubber is sprinkled in the form of powder on the metal surface and then it is attached to the surface using heat or glue.

The cost of using rubber lining

You know that in the field of industry, it is not possible to set a fixed price for a product. For this, one should pay attention to various things in that field and then announce the final price to the customer. The cost of using rubber lining depends on various factors. One of the most influential factors is the size and shape of the metal surface. The larger or more complex the metal surface, the more expensive the rubber lining will be. Another effective factor is the type of tire used. The type of rubber used also affects the cost of rubber lining. More durable tires are usually more expensive. But the third factor affecting the cost of this product is its implementation method. You know that this work is done in two ways: powder and sheet. The sheet method is usually more expensive than the powder method.

Suitable industries for using rubber lining

chemical industry

In the chemical industry, rubber linings are used to protect tanks, pipes, and other equipment against chemical corrosion and wear.

Oil and Gas

In such industries, these rubbers are used to protect tanks, pipes, and other equipment against the corrosion and wear of oil and gas fluids.

Food industry

In the food and beverage industry, rubber linings are used to protect tanks, pipes, and other equipment from food and beverage corrosion and wear.

Water and Wastewater

In the water and wastewater industry, rubber lining is used to protect tanks, pipes, and other equipment against corrosion and wear from water and wastewater.

Thank you for joining us in this article. As you have seen, in this article we introduced and reviewed rubber lining. Rubberlining is an effective protective coating that can protect metal surfaces from corrosion, wear, impact, and other damage. This coating has wide applications in various industries and can increase the useful life of equipment and reduce maintenance costs. If you manage an industrial unit, never forget to use this useful product. The use of rubber covers helps a lot in the growing trend of workshops. Mabanapaya Industrial Group, specialized in the production of all kinds of rubber linings, is ready to receive your orders. You can contact us for more information and free consultation.